Think of automated purchase orders as an intelligent autopilot for your store's inventory. Instead of late nights drowning in spreadsheets and pure guesswork, this kind of system uses real-time sales data to automatically generate and send purchase orders to your suppliers. It’s a huge leap from reactive crisis management to proactive, data-driven inventory control.

We’ve all been there: it's midnight, and you're manually combing through sales reports, desperately trying to figure out if you need to restock your bestseller before the weekend rush. This familiar chaos is where manual inventory management fails modern e-commerce brands. It’s painfully slow, wide open to human error, and a massive drain on your most valuable resource—time.

Automated purchase orders wipe this entire process off your plate. The system plugs directly into your sales channels, like a Shopify store, and keeps a constant watch on your stock levels. When a product’s inventory dips to a pre-set threshold (your reorder point), the system instantly creates a purchase order. It can even send it directly to your supplier for fulfillment, all without you lifting a finger.

Let’s be clear: this isn't just about convenience. It’s a fundamental change in how you run your operations. Before diving deeper, it helps to have a solid grasp of what purchase orders are and the part they play in the supply chain. Once that’s clear, the value of automating them becomes impossible to ignore. You stop reacting to stockouts and start proactively maintaining perfect inventory levels.

The market for this kind of tech is exploding—it's projected to hit $4.85 billion by 2029. Brands already using AI-driven procurement are reporting a 30-50% reduction in their purchasing cycle times. That’s a massive amount of time freed up for managers to focus on strategy instead of mind-numbing data entry.

By automating routine procurement, you’re not just saving hours of admin work. You're building a more resilient, accurate, and profitable business that can scale without being held back by manual bottlenecks.

This transition transforms your workflow from a constant source of stress into a serious competitive advantage. It makes sure your most popular products are always in stock, which keeps customers happy and protects your revenue streams. To learn more, check out our complete guide on advanced inventory management strategies.

To really see the difference, let’s put the old way and the new way side-by-side. The contrast highlights just how much of a game-changer automation can be for a growing e-commerce brand.

| Feature | Manual Purchase Orders | Automated Purchase Orders |

|---|---|---|

| Process | Manual data entry, spreadsheet tracking, email communication | System-driven, real-time data integration, automated alerts |

| Speed | Slow and delayed, often taking hours or days | Instantaneous, generated and sent in minutes |

| Accuracy | Prone to human error (typos, miscalculations) | Highly accurate, based on live sales and inventory data |

| Scalability | Becomes a major bottleneck as order volume grows | Scales effortlessly with your business |

| Labor Cost | High, requires significant staff time for admin tasks | Low, frees up team members for strategic work |

| Stockouts | High risk due to delays and guesswork | Minimized risk through proactive reordering |

As you can see, sticking with a manual process in today's fast-paced market is like trying to win a race on foot while your competitors are in cars. Automation gives you the speed, accuracy, and efficiency you need to pull ahead.

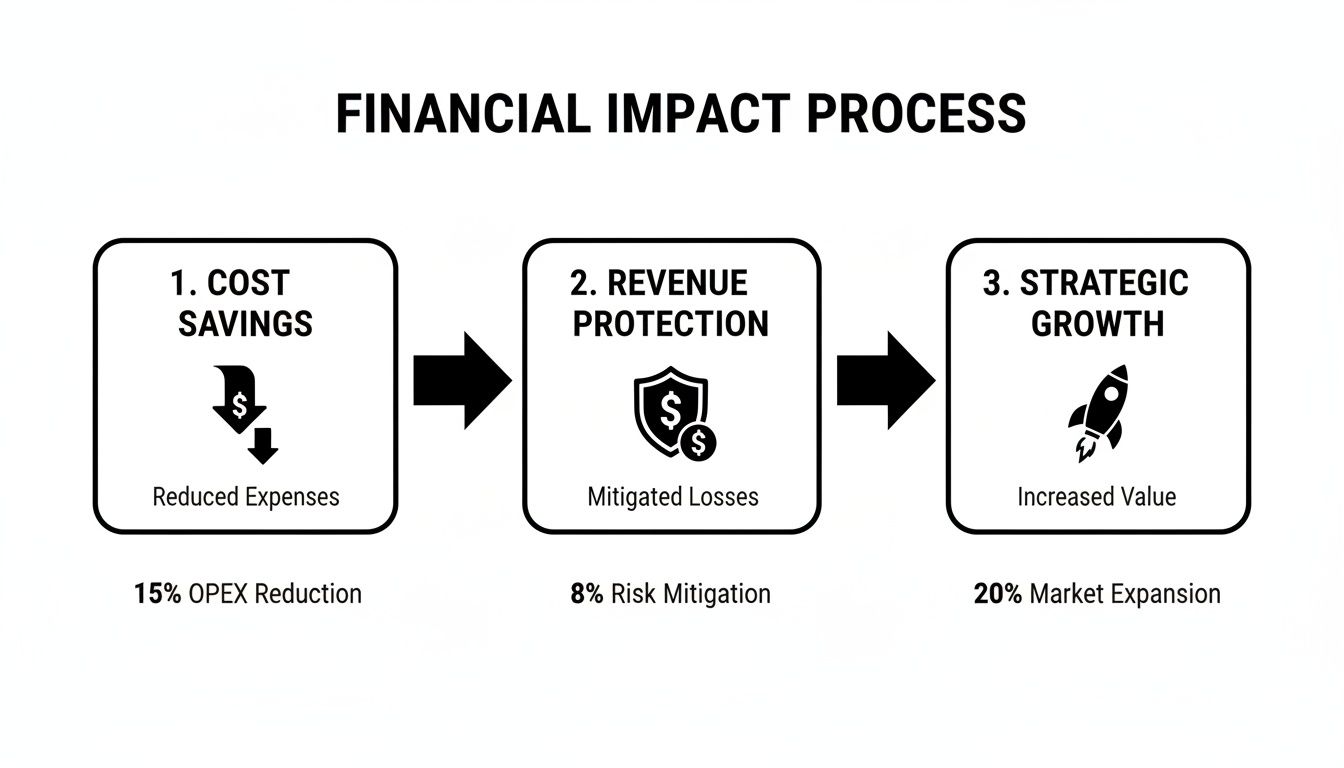

Automating your purchase orders isn't just a small tweak to your workflow; it's a serious investment in your bottom line. The financial upside ripples through your entire business, starting with cost reductions you can see and measure almost immediately. Think about all the hours your team sinks into manually counting stock, wrestling with spreadsheets, and sending emails back and forth with suppliers. That’s pure administrative overhead.

When you bring in automated purchase orders, you’re not just trimming the fat—you're getting rid of those tasks completely. This frees up your team to focus on things that actually move the needle, like marketing, product development, or talking to customers. You're not just saving on labor; you're re-investing your people's time into activities that generate real growth.

Beyond the direct savings, automation is one of the best ways to protect your revenue. For any e-commerce brand, a stockout on a hot product is a silent profit killer. It’s especially painful during peak seasons or when an item suddenly goes viral on social media. Every "notify me when back in stock" click is a lost sale and, quite possibly, a lost customer.

Automated systems are your best defense against this. They keep your bestsellers on the shelf by using real-time data to reorder proactively, making sure you never miss a sales opportunity because of a preventable stockout. Your inventory stops being a liability and starts becoming the reliable, revenue-generating asset it’s supposed to be.

The real ROI isn't just in the money you save on administrative tasks. It's in the sales you don't lose, the customers you retain, and the market opportunities you're finally equipped to capture.

This fundamental shift is why the purchase order software market is exploding, projected to become a $46.4 billion industry by 2033. For merchants, especially in fast-moving industries like food and beverage, the ability to slash procurement cycle times by up to 35% is a game-changer. You can dig deeper into this trend by checking out the full report on purchase order software growth.

Finally, the financial impact goes even further, improving your supplier relationships and overall cash flow. When your orders are consistently accurate and on time, it builds a massive amount of trust with your suppliers. That kind of reliability can open the door to better payment terms, preferential treatment when stock is tight, and even volume discounts down the road.

The process doesn't stop at just creating the PO, either. The benefits flow through the entire procure-to-pay cycle, including crucial steps like supplier payment automation. When your whole financial workflow is in sync, you get a much clearer picture of your cash flow, cut down on costly ordering mistakes, and put your brand in a position for steady, profitable growth.

Think of an automated purchase order system as a smart thermostat for your inventory. A basic thermostat just kicks on when the room gets too cold. In the same way, a simple automation tool reacts when your stock hits a pre-set low point. But an intelligent, AI-powered system? That’s like a thermostat that anticipates a cold front rolling in, adjusting proactively. It sees what's coming for your business and prepares for it.

This whole process gets going by tapping into the core data streams that are the lifeblood of your e-commerce store. It's not just looking at one piece of the puzzle; it's watching the constant, real-time flow from several critical areas.

An automated PO system is only as sharp as the information it’s fed. To get a clear, up-to-the-minute picture of what your business needs, it continuously pulls from three main sources:

Once these data streams are hooked up, the system can start applying its logic to make smart purchasing decisions for you.

The real engine behind all this is a combination of triggers and forecasting. A trigger is just a rule you set that tells the system when to jump into action. The most common one is the reorder point—a specific stock level that, once hit, automatically fires off a new purchase order.

But the true magic happens when AI-powered demand forecasting joins the party. Instead of just reacting to a static number, the system learns from your sales history. It spots seasonal trends and can even predict future spikes in demand before they happen.

This means the system can proactively suggest a bigger purchase order before your Black Friday rush, instead of just reacting when you’re already scraping the bottom of the barrel. It shifts your inventory management from reactive to predictive.

This infographic breaks down how these data-driven decisions translate directly into dollars and cents.

As you can see, the benefits compound, moving from direct cost savings to protecting revenue and fueling real strategic growth.

This level of insight is why adoption is exploding. The global procurement software market, which is the engine for these systems, hit $9,273.6 million in 2024 and is on track to more than double by 2033. It’s not just hype; companies using this tech report 35% faster procurement cycles, which is huge for cutting down on those profit-killing stockouts. You can dig into more data on the growth of procurement software on Grand View Research.

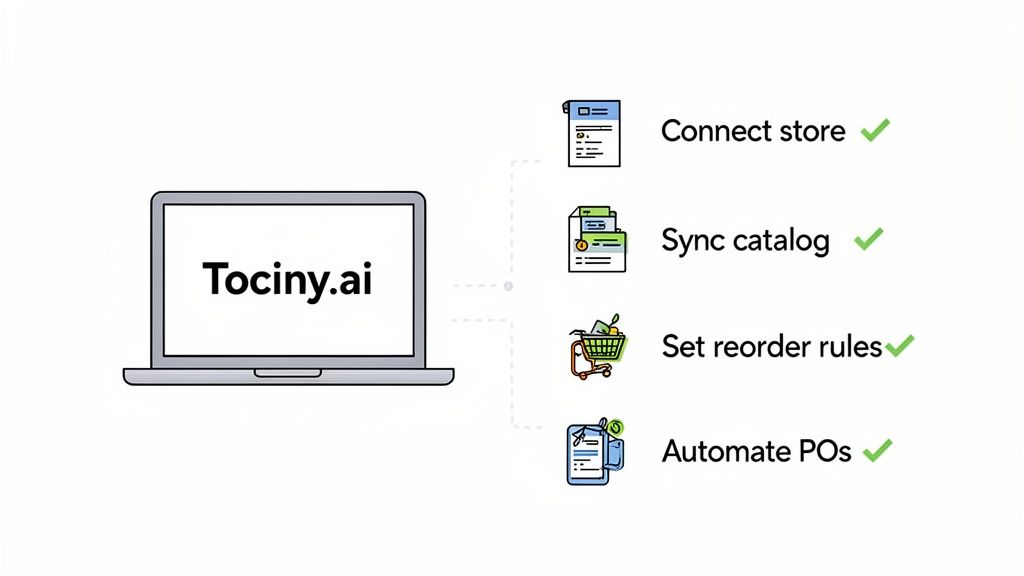

Platforms like Tociny.ai are at the center of this shift, giving you a bird’s-eye view that feeds sales history and trend alerts right into the PO process for incredibly precise inventory control. By bringing all these elements together, an automated system makes sure you have exactly what you need, right when you need it. You can see more on how Tociny.ai integrates these components to turn data into action.

Making the jump to automated purchase orders might seem like a huge technical hurdle, but with a platform like Tociny.ai, the process is surprisingly straightforward. It's built from the ground up for Shopify merchants. We're not talking about ripping out your existing operations. Instead, it’s a clear, step-by-step path from manual data entry to smart, data-backed purchasing. The end game? Putting your inventory replenishment on autopilot, guided by AI that actually understands your business.

The entire setup is designed to feel empowering, not intimidating. It all begins when you connect your Shopify store. This simple step allows Tociny.ai to sync your product catalog and—most importantly—your historical sales data. This is the foundation for everything. It’s the raw material the AI needs to learn the unique sales rhythm of your brand.

Once you're connected, the real magic starts. Tociny.ai's forecasting engine dives into your sales history, analyzing past performance to spot trends and pull out crucial inventory insights. You’ll stop staring at spreadsheets and start understanding the story your sales data is trying to tell you.

With those insights in hand, you can begin setting the rules that will drive your automation. Forget guessing your reorder points. Now you can establish smart thresholds based on data-backed recommendations, turning those insights into tangible action.

The real leap forward here is moving beyond basic "if this, then that" logic. With AI, you’re building a system that actually adapts to your sales patterns. It keeps you prepared for both the busy seasons you expect and the surprise sales spikes you don’t.

The last piece of the puzzle is switching on your automated workflows. With your rules dialed in, Tociny.ai will automatically generate draft purchase orders the moment your criteria are met. But—and this is critical—you’re always in the driver's seat. These POs land in an approval queue, giving you the final say on every single order before it goes out to a supplier. It’s the perfect blend of machine efficiency and human expertise.

This setup doesn't just save you from hours of mind-numbing work; it drastically cuts down the risk of painful stockouts and costly overstocking.

If you want to get into the nitty-gritty, you can learn more about Tociny.ai's advanced purchase order features and see how they plug directly into Shopify. This hands-on, analytics-powered approach makes switching to automated purchase orders a practical and game-changing upgrade for any e-commerce brand.

So, you've set up an automated purchase order system. Great. But how do you know if it's really working? It's easy to see the time you're saving, but the true value is buried a little deeper—in the numbers that dictate your store's financial health.

Tracking the right key performance indicators (KPIs) is how you get the real story. This is what turns inventory management from a guessing game into a strategic advantage. It gives you a clear, objective scorecard to prove that your investment in automation is paying off.

Think of these metrics as the vital signs for your e-commerce business. Monitoring them tells you exactly how efficient your new system is and points to where you can still tweak and improve. To start, you'll want to keep a close eye on these three critical indicators:

Inventory Turnover Rate: This tells you how many times you sell and replace your entire stock over a certain period. A higher number is a great sign—it means your products are flying off the shelves and you're not tying up cash in slow-moving items. A low rate, on the other hand, can be a red flag for overstocking.

Stockout Rate: This is the percentage of times a customer tried to buy something, but you were out of stock. It's a direct hit to your revenue and customer trust. A solid automated system should bring this number way down, protecting you from those frustrating (and costly) "out of stock" notifications.

Procurement Cycle Time: This measures the total time it takes from the moment a purchase order is created to when the goods actually land in your warehouse. Automation slashes this cycle by cutting out all the manual back-and-forth. A shorter cycle means your cash isn't locked up in transit, and you can react much faster to what your customers want.

By tracking these KPIs consistently, you move from feeling like your inventory is in good shape to knowing it is. This is the hard data you need to justify the investment and make smarter strategic moves down the road.

When you see these numbers improve, you'll see the real-world benefits stack up. A faster turnover boosts your cash flow. A lower stockout rate builds customer loyalty. And a shorter procurement cycle makes your whole operation more agile. Together, they create a much more resilient and profitable business.

To really dig into the performance of your automated system, you need a clear dashboard of metrics. The table below breaks down the most important KPIs, explaining what they measure and why they are so crucial for your bottom line.

| KPI | What It Measures | Why It Matters |

|---|---|---|

| Inventory Turnover Rate | The speed at which you sell and replenish your entire inventory. | A high rate indicates strong sales and efficient use of capital. It prevents cash from being tied up in unsellable stock. |

| Stockout Rate | The frequency of items being unavailable when a customer wants to buy. | Directly impacts lost sales and customer satisfaction. A low rate means you're meeting demand and retaining customers. |

| Procurement Cycle Time | The total time from creating a PO to receiving the inventory. | A shorter cycle improves agility and reduces the amount of cash tied up in the supply chain, allowing you to respond to trends faster. |

| Carrying Costs of Inventory | The total cost of holding unsold inventory (storage, insurance, obsolescence). | Automation helps lower this by preventing overstocking, which directly increases your profit margins. |

| Perfect Order Rate | The percentage of orders shipped without any issues (e.g., wrong items, damage, delays). | Reflects the accuracy and efficiency of your entire fulfillment process, from procurement to delivery. |

| Supplier Lead Time | The time it takes for a supplier to fulfill your purchase order. | Accurate lead time data is essential for automated reordering systems to function correctly and prevent stockouts. |

Tracking these metrics gives you a holistic view of your inventory health. It provides the concrete feedback needed to refine your automation rules, negotiate better terms with suppliers, and ultimately build a more profitable e-commerce operation.

It’s tempting to flip the switch on automated POs and just walk away, but that’s one of the quickest ways to run into trouble. True, long-term success means sidestepping a few common pitfalls, and the biggest one is treating your shiny new system like a "set it and forget it" appliance.

The reality is your business, your suppliers, and your customers are always in flux. Automation rules that were perfect last quarter might be completely out of sync with new sales trends or a change in supplier lead times. You have to keep an eye on things. A periodic review ensures your system evolves with you, preventing it from making outdated purchasing decisions that tank your inventory health.

Think of your automation rules not as permanent laws, but as a living strategy. It needs a tune-up every now and then to keep performing at its peak, just like any other critical part of your business.

Another massive mistake is letting your data quality slide. Your automated system is only as smart as the information you feed it. If your inventory counts are off or your supplier lead times are just wishful thinking, you’re just automating bad decisions and making mistakes at lightning speed. Making sure your data is clean and accurate isn't just a suggestion—it's non-negotiable.

And don't forget the human element. While the system is busy firing off orders, it's still on you to maintain those crucial supplier relationships. A machine can't build rapport. Give your suppliers a heads-up about your new process to make sure everyone is on the same page and to head off any confusion before it starts.

Here’s a quick-and-dirty guide to avoiding these common headaches:

Let's tackle some of the common questions and concerns that pop up when e-commerce founders and managers first look into automating their purchase orders. It's natural to be curious—and a little skeptical—so let's clear the air and talk about what this really means for your brand.

Not a chance. In fact, it's the complete opposite. This is probably the number one fear we hear, but automated purchase orders are built to give you more meaningful control, not less.

Think of it this way: modern systems have approval workflows baked right in. The software does the heavy lifting—analyzing the data, running the forecast, and drafting the PO—but it always lands in a queue for your final sign-off. You still have the final say before a single dollar is spent or an order is sent. You're simply swapping manual number-crunching for strategic oversight.

Definitely not. While a business with stable, predictable sales will certainly benefit, automation is a true game-changer for brands with dynamic, fluctuating demand. Static reorder points just can't keep up when sales are all over the place, which is why so many growing brands swing between frustrating stockouts and cash-draining overstock.

This is where AI-powered forecasting really flexes its muscles. It digs into your sales history to spot the subtle trends, seasonal lifts, and sudden spikes that are nearly impossible to catch manually. This makes automation an incredible asset for any brand navigating rapid growth or unpredictable sales patterns, helping you stay one step ahead of your customers.

The goal of automation isn't to replace your judgment. It’s to arm you with better data. It handles the tedious calculations so you can focus on the big-picture decisions that actually grow your business.

The timeline really depends on the tool you choose. Some simple, off-the-shelf apps can be up and running in a few hours, giving you a quick win with basic automation.

For a more powerful setup, you'll likely go through a guided onboarding process. This is where the magic happens. A specialist will help tune the system to your specific business, from pulling in historical data to configuring the forecasting models just right. This more thorough setup might take a few weeks, but the investment pays off massively in long-term accuracy and ROI.

Ready to stop guessing and start making inventory decisions based on solid data? See how Tociny.ai uses AI to give you a clear, actionable view of your sales and stock levels. Get early access and see what's possible.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.