Stock replenishment isn't just a boring logistics task—it's the strategic process of getting inventory where it needs to go, right when it needs to be there. Think of it as the heartbeat of your supply chain, ensuring products are in the right place at the right time to meet customer demand. It’s a constant balancing act between preventing those dreaded stockouts and avoiding the cash-flow killer that is overstock.

Imagine your Shopify store is a bustling neighborhood café. A dialed-in replenishment of stock strategy means you never, ever run out of your best-selling coffee beans during the morning rush. It also means you aren't tossing out stale pastries at closing time. This isn’t just about moving boxes; it’s a powerful engine for growth and customer happiness.

When you nail this, you have the perfect amount of product ready to ship the moment a customer clicks "buy." This sweet spot is the key to unlocking higher profits, building a base of fiercely loyal customers, and ultimately, creating a scalable e-commerce business. The entire success of your operation really hangs on how well you can replenish your inventory.

A sloppy replenishment process creates two massive, expensive problems that can quietly drain your profitability. Each one is a huge missed opportunity and a direct hit to your bottom line.

A good replenishment process keeps your shelves full and your finance team smiling. A bad one? It's nothing but headaches.

When you start treating the replenishment of stock as a strategic function, your whole perspective shifts. You move from simply reacting and placing orders to proactively planning your business. It forces you to get intimate with your demand patterns, optimize your cash flow, and build stronger relationships with your suppliers.

Beyond just the numbers, optimizing your physical logistics can be a game-changer. For instance, digging into cost-saving, space-saving shipping methods can dramatically improve your warehouse efficiency and directly support your replenishment goals by freeing up both capital and physical space.

Ultimately, a smart replenishment system transforms your inventory from a necessary cost into a dynamic asset that drives growth, delights your customers, and gives you a serious competitive edge.

Picking a method for the replenishment of stock is a lot like choosing the right navigation app for a road trip. The best one isn't always the one with the most features; it's the one that fits your destination, your vehicle, and the traffic you expect to hit. Each strategy gives you a different way to answer that fundamental question: "When and how much should I reorder?"

Getting this right is the first big step toward a solid inventory system. It lays the foundation, the core logic that will drive your purchasing decisions. It’s how you move from guesswork to aligning your inventory with what your customers actually want.

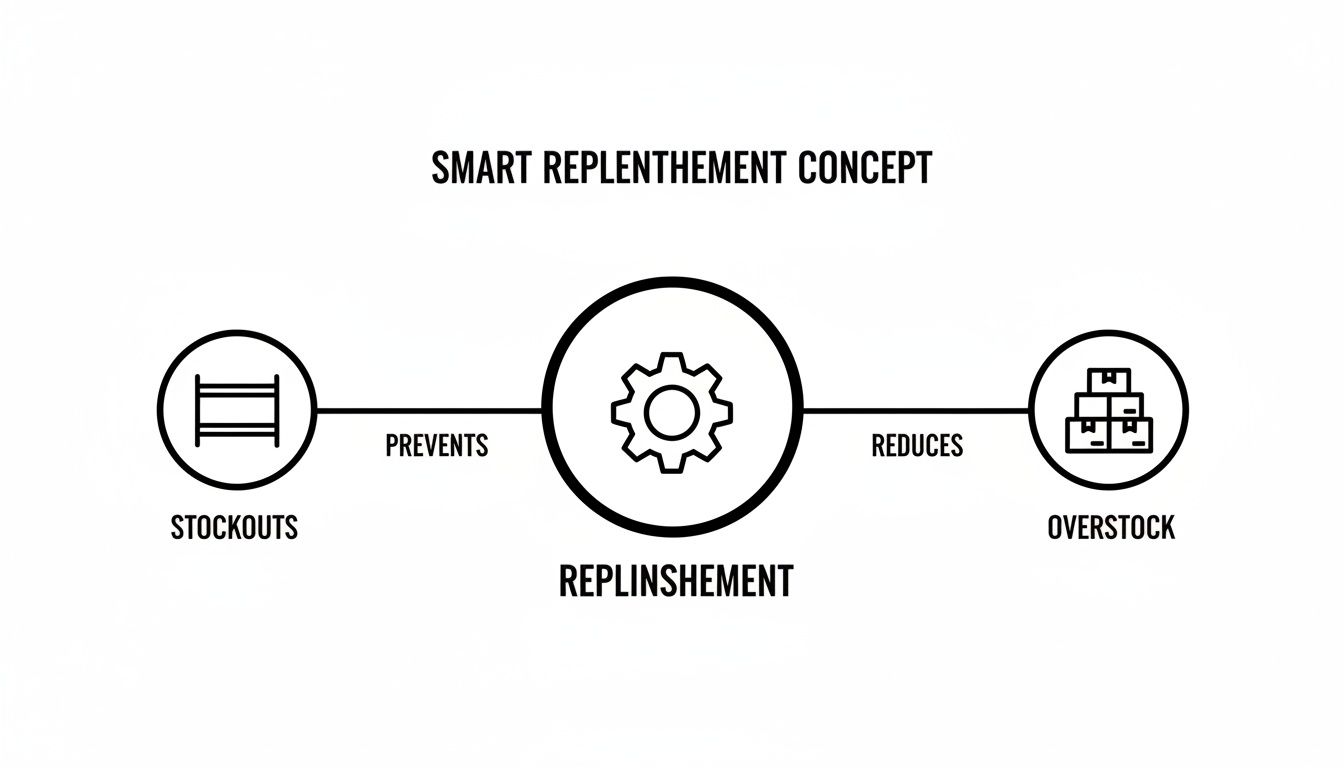

This visual shows exactly how a smart replenishment strategy acts as the central gear, connecting your efforts to stop stockouts and slash overstock.

As you can see, effective replenishment is all about balance. It’s the critical function that directly fights the two biggest inventory headaches: lost sales from empty shelves and wasted cash from excess stock.

The Reorder Point (ROP) method is as straightforward as it gets. Think of it like the low fuel light on your car's dashboard. It doesn’t tell you to get gas every Monday morning. Instead, it flashes a warning only when your fuel drops to a specific, critical level.

In your warehouse, it works the same way. You set a minimum stock level for each product. The moment your inventory hits that number, it’s the trigger to place a new order. This is a reactive, event-driven system, and it’s perfect for products with stable, predictable demand.

It works best when you can confidently answer the question: "At what exact stock level do I need to reorder to make it through until the new shipment arrives?"

The Periodic Review model flips the script. It operates on a fixed schedule, not a fixed inventory level. This is your classic weekly grocery run. You don't zip to the store the second you run out of milk; you go every Saturday and top up everything you need for the week ahead.

With this approach, you check your inventory at set intervals—be it daily, weekly, or monthly. During each check-in, you place an order to bring your stock back up to a predetermined maximum level. The amount you order will be different every time, depending on how much you sold.

This system is great for simplifying logistics, especially if you order multiple SKUs from the same supplier, as you can bundle all your purchase orders into one predictable schedule.

Economic Order Quantity (EOQ) is for the numbers people. It’s a formula-driven approach laser-focused on finding the perfect balance between two competing costs: ordering costs and holding costs. Ordering in huge quantities usually gets you a better price per unit, but it also means paying more to store all that extra product.

Think about buying paper towels. A single roll is expensive, but a 24-pack is a great deal. The catch? You need a place to stash all those extra rolls. EOQ is the math that tells you the exact quantity to order to keep your total costs at an absolute minimum.

The goal of EOQ is to find the financial 'sweet spot' where the money you save on ordering fees and bulk discounts is perfectly balanced by the cost of holding the inventory.

This model is a game-changer for brands that want to optimize their cash flow, making sure they aren't bleeding money on either too-frequent small orders or massive, oversized ones.

Just-in-Time (JIT) is an ultra-lean strategy where you receive goods from suppliers only as they’re needed—either for production or to fulfill a customer order. It's the inventory equivalent of a high-end sushi restaurant that gets a fresh fish delivery every single morning. They don’t stockpile tuna for a month; they order just enough for that day to guarantee peak freshness and zero waste.

This method can radically cut your inventory holding costs and virtually eliminate the risk of products becoming obsolete. But there’s a major catch: it demands an incredibly reliable and lightning-fast supply chain. Even a small delay can trigger an immediate stockout.

A successful JIT system is built on strong supplier relationships, precise demand forecasting, and a hyper-efficient logistics network. It's a high-risk, high-reward play best suited for businesses with predictable demand and absolutely rock-solid suppliers.

Choosing between these models isn't about finding the "best" one overall, but the best one for your specific products and operational realities. A business selling perishable goods will have vastly different needs than one selling non-perishable, high-volume items.

This table breaks down the core differences to help you decide.

| Strategy | Best For | Key Advantage | Potential Downside |

|---|---|---|---|

| Reorder Point (ROP) | Products with stable, predictable demand. Businesses that prefer a simple, trigger-based system. | Easy to implement and automate. Minimizes the risk of stockouts for steady sellers. | Can lead to overstock if demand suddenly drops. Less efficient for managing many SKUs. |

| Periodic Review | Businesses managing many SKUs from the same supplier or with limited ordering capacity. | Simplifies logistics and planning with a predictable ordering schedule. Reduces administrative overhead. | Higher risk of stockouts between review periods. May require larger safety stock. |

| Economic Order Quantity (EOQ) | High-volume products with stable demand and predictable ordering/holding costs. | Optimizes cash flow by minimizing total inventory costs (ordering + holding). | Based on assumptions that can be hard to predict (e.g., demand, costs). Less flexible to market changes. |

| Just-in-Time (JIT) | Businesses with strong supplier relationships, predictable demand, and short lead times (e.g., automotive, high-end food). | Drastically reduces holding costs and waste. Frees up working capital. | Extremely vulnerable to supply chain disruptions. Any delay can cause immediate stockouts. |

Ultimately, many businesses don't stick to just one strategy. They often use a hybrid approach, applying different models to different product categories based on value, demand volatility, and supplier reliability. The key is to understand the trade-offs of each and align your choice with your business goals.

Even the sharpest replenishment strategy will fall flat without two critical pieces: safety stock and a firm grip on lead time.

Think of it like this: your main replenishment strategy is the engine of your business. But safety stock is the spare tire in the trunk, and lead time is the ETA on your GPS. You absolutely need both to avoid getting stranded. Getting these two elements right is what separates businesses that are always scrambling from those that have a resilient, proactive approach to stock replenishment.

They act as a buffer, smoothing out the inevitable bumps in the road from both unpredictable customer demand and shaky supplier reliability.

This kind of protection has become non-negotiable. Small and medium-sized businesses have been walking a tightrope. A 2025 benchmark report found that 30% of SMBs are now intentionally over-ordering certain products as a "strategic" buffer against supply chain chaos.

But there's a flip side. The same report revealed that for 17% of these businesses, over a tenth of their inventory sat gathering dust for more than a year. It’s a delicate dance between being prepared and accidentally creating a warehouse full of dead stock.

So, what is safety stock? It's simply the extra inventory you keep on hand to guard against surprises. It’s your emergency fund for products, shielding you from a sudden rush of sales or an unexpected delay from your supplier.

Without it, one small hiccup can spiral into a stockout, costing you sales and frustrating your customers.

The goal isn't to just pile up mountains of extra product "just in case." It's about calculating a precise buffer that protects your service levels without racking up huge carrying costs. A great starting point is this simple formula:

(Maximum Daily Sales x Maximum Lead Time in Days) – (Average Daily Sales x Average Lead Time in Days)

This formula forces you to consider the worst-case scenario for both demand and supply, making sure you have just enough stock to weather the storm. For a closer look, you might want to dive deeper into how to calculate safety stock with more advanced methods.

Lead time is the total clock time from the second you hit "send" on a purchase order to the moment that inventory is on your shelves and ready to sell. In today's volatile world, just guessing at this number is a recipe for disaster.

To track it accurately, you have to break it down into its individual parts:

By tracking each of these stages, you get a crystal-clear picture of your real supply timeline. This isn't just data for data's sake; this visibility lets you set smarter reorder points and keep customers happy without bloating your inventory with expensive, unnecessary stock.

A replenishment strategy is only as good as the results it delivers. But how do you know if your meticulously planned system is actually working? You need a clear report card, and that’s where Key Performance Indicators (KPIs) come in.

Tracking the right metrics transforms your replenishment of stock from a series of tasks into a measurable, optimizable business function. These numbers tell the true story of your inventory health, exposing hidden costs and highlighting opportunities you might be missing. They are the essential feedback loop for making smart, data-driven decisions.

Think of your inventory as cash sitting on a shelf. The Inventory Turnover Ratio tells you how quickly you’re converting that shelved cash back into actual revenue. A high ratio is a sign of a healthy, efficient business with products that are flying off the shelves.

A slow or declining turnover rate, on the other hand, is a major red flag. It often means your capital is tied up in slow-moving or obsolete products, which can quickly lead to serious cash flow problems. It’s a direct measure of how well your buying habits align with what your customers actually want.

While turnover gives you a big-picture view, the Sell-Through Rate zooms in on how a specific product is performing. Calculated as a percentage, it compares the number of units you sold against the number you received from your supplier over a set period.

For example, if you brought in 100 units of a new skincare product and sold 85 within the first month, your sell-through rate is a solid 85%. This metric is incredibly valuable for spotting your star performers and your duds, allowing you to adjust your stock replenishment for specific SKUs with laser precision.

A strong sell-through rate signals a great product-market fit and an effective sales strategy. A poor rate tells you it might be time to rethink your purchasing decisions or marketing for that particular item.

The Stockout Rate is one of the most painful—and critical—KPIs because it directly measures missed opportunities. It calculates the percentage of orders you couldn’t fill right away because an item was out of stock. Every time this happens, you don't just lose a sale; you risk losing a customer for good.

Keeping this number as close to zero as possible should be a top priority for any replenishment strategy. A consistently high stockout rate is a clear sign that your safety stock levels, lead time calculations, or demand forecasts are failing you.

Finally, Carrying Costs (or holding costs) pull back the curtain on all the hidden expenses of just owning inventory. This metric isn't just about the purchase price of a product; it includes everything you pay to keep it sitting in your warehouse:

Tracking your carrying costs helps you understand the true financial weight of overstocking. It reinforces the importance of a lean, efficient replenishment system that minimizes how much time your products spend gathering dust on your shelves. You can learn more about how this impacts your financial health in our guide to Days Inventory Outstanding.

For years, managing the replenishment of stock meant staring at a sprawling spreadsheet, trying to make sense of past sales and hazard a guess about the future. It was slow, clunky, and riddled with human error—a system that just can't keep up with the breakneck speed of e-commerce today. It's like trying to navigate a highway with a paper map while everyone else has a real-time GPS.

Artificial intelligence (AI) is the GPS your inventory has been waiting for. Instead of relying on gut feelings or simplistic averages from last year, AI-powered platforms act as an intelligent co-pilot. They crunch massive amounts of data in seconds—far more than a person ever could—to give you precise, actionable insights.

Traditional methods usually fall short because they can't account for all the little variables that influence what customers buy. A spreadsheet doesn’t understand seasonality, upcoming holidays, subtle market trends, or how that marketing campaign you just launched might affect a specific product's sales.

AI-driven systems, on the other hand, are built to thrive on this complexity. They connect the dots between dozens of data points, shifting you from basic reporting into the realm of predictive analytics. This is the fundamental leap from being reactive to proactive with your stock.

Instead of just showing you what sold last month, AI tells you what’s likely to sell next month—and exactly how much you’ll need to order.

This capability is a huge reason why the global Inventory Optimization Market is expected to jump from USD 5.87 billion in 2025 to USD 12.42 billion by 2032. This growth is being driven by D2C brands in competitive niches like fashion and wellness that need sharper forecasting to stay ahead.

The real magic of AI in inventory management isn't just its analytical power; it's how it turns all that complex data into simple, clear instructions. A platform like Tociny.ai won't overwhelm you with dense charts and endless tables. It cuts through the noise and gives you a clear directive.

Imagine getting a notification that says, "Order 75 units of SKU-ABC by Tuesday to prevent a stockout." That's AI in action. It’s already considered your forecast, supplier lead times, and current stock levels to give you a single, straightforward task.

The system automatically projects future demand, turning a mess of historical data and market signals into a clean roadmap for your purchasing. If you want to go deeper on this, check out our guide on https://tociny.ai/blog/ai-demand.

For a busy Shopify store owner, bringing AI into your replenishment process delivers immediate and powerful results. It automates the tedious, mind-numbing work of data analysis, freeing you up to focus on what really matters: growing your business.

Here's what that looks like in practice:

Ultimately, AI turns your inventory from a reactive headache into a strategic asset. It gives you the power to make smarter, faster, and more profitable decisions, ensuring you have the right products on the shelf at the right time. To get a broader perspective on its power, you can learn more about how to implement AI in e-commerce brands.

Even with a great strategy on paper, the road to perfect stock replenishment has a few potholes. It’s easy to fall into some common traps that quietly sabotage your efforts, leading you right back to the stockouts and overstock you’re trying to escape. Spotting these pitfalls is the first step to building an inventory system that actually works.

One of the biggest mistakes is treating all your products the same. A "one-size-fits-all" ordering schedule is like giving every plant in a garden the same amount of water—some will thrive, but others will wither. Your best-sellers need a completely different replenishment rhythm than your slow-moving, high-margin items.

Another classic blunder? Forgetting to factor in your supplier's performance. You can have the world's most accurate demand forecast, but if your supplier is consistently late or short-ships your orders, the whole system crumbles. Ignoring unreliable lead times is a surefire way to end up with stockouts and unhappy customers.

You need to track your supplier metrics as obsessively as you track your own sales. Keep an eye on:

Treating a supplier's quoted lead time as a guarantee instead of a variable is a recipe for disaster.

Only looking at last year's sales to predict future demand is like driving while staring in the rearview mirror. While historical data is a great place to start, it completely misses what's happening now—new trends, shifting market dynamics, or sudden economic changes. If the last few years have taught us anything, it's that the past isn't always a good predictor of the future.

Over-reliance on past performance leaves you exposed. A smart replenishment strategy has to pull in forward-looking signals to stay agile and react to what’s happening in the market today and what might be coming tomorrow.

This is especially true in a volatile economy. Recent data shows just how much global supply chain instability is shaping replenishment. The GEP Global Supply Chain Volatility Index hit -0.29 in late 2023, signaling a major slowdown as manufacturers cut back on purchasing. In this climate, cost control has become the top priority for 33% of global leaders. You can dig into the full findings on global supply chain volatility to see the bigger picture.

By sidestepping these common traps—treating all products the same, ignoring supplier issues, and getting stuck in the past—you can plug the hidden leaks in your process. This proactive approach will make your replenishment system tough enough to handle the real world of e-commerce before any problems can hurt your bottom line.

Diving into the nitty-gritty of stock replenishment can stir up a lot of questions. It’s one thing to understand the concepts, but another to feel confident putting them into practice in your own Shopify store. Let's tackle some of the most common questions we hear from merchants just like you.

Think of this as your go-to cheat sheet for the practical challenges you'll face while fine-tuning your inventory flow.

There’s no magic number here. The right frequency really boils down to your replenishment strategy and how fast your products fly off the shelves.

If you’re using a Reorder Point (ROP) system, your software is doing the heavy lifting, keeping a constant watch on your stock. An order gets triggered the second you hit that minimum threshold. But if you’re on a Periodic Review model, you’ve set the schedule—maybe weekly for your bestsellers or monthly for items that move a bit slower. The goal is to sync your review cadence with your sales cycle so you never get caught with empty shelves between checks.

It’s easy to get these two tangled up, but they cover different parts of the inventory journey. Here’s a simple way to think about it:

Essentially, procurement sets the stage, and the replenishment of stock is the performance that happens on it every single day.

Absolutely. When you're just launching and have a handful of SKUs, a spreadsheet is a fantastic starting point. It’s a zero-cost way to get your feet wet, tracking sales, stock levels, and reorder points. You'll get a real feel for the basic mechanics of inventory management.

But fair warning: you will outgrow it, and probably faster than you think. As your product catalog gets bigger and sales pick up, that trusty spreadsheet quickly becomes a liability. It's clunky, a magnet for human error, and completely blind to the predictive insights you need to scale.

A spreadsheet can't forecast demand around a sales event or adjust for a sudden trend. That’s where its limitations become a real risk to your business. It's the perfect training ground, but it’s not a long-term solution for an ambitious e-commerce brand that needs a smarter system for stock replenishment.

Ready to graduate from spreadsheets and stop guessing? Tociny.ai uses AI to give you clear, actionable inventory recommendations that wipe out stockouts and kill overstock. It’s time to take firm control of your inventory and plan for profitable growth. Get early access to Tociny.ai today.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.