Imagine your business is a restaurant. Your inventory is all the fresh ingredients in the kitchen, and logistics is the team of waiters hustling to get the perfect dish to the table. One simply can't function without the other. This is the core of how inventory management and logistics work together—they're the real engine that drives profitability in e-commerce.

In the direct-to-consumer (D2C) world, the customer experience doesn't just stop at the checkout button. It truly ends when the right product lands on their doorstep, on time and in one piece. That final, crucial step is where the magic between inventory and logistics happens. Treating them as separate functions is like having a chef who refuses to talk to the front-of-house staff—a recipe for chaos, delays, and unhappy customers.

When these two are out of sync, profit-killing mistakes start to pile up. What good is a brilliant demand forecast if your warehouse can't get orders out the door during a flash sale? On the flip side, even the world's most efficient shipping network is useless if the product is out of stock. This guide is all about untangling that relationship and showing you how to build an operation that’s both resilient and profitable.

Today's shoppers expect two things: speed and reliability. That puts a ton of pressure on D2C brands to nail every single part of their supply chain. The old days of tracking stock on a spreadsheet are over. Brands are waking up to the fact that they need smarter, more connected systems to keep up. If you want to see just how many moving parts there are, exploring different logistics use cases can give you a real sense of the complexity involved.

This push for efficiency is fueling huge investments in technology. The global inventory management software market was valued at USD 3.9 billion in 2024 and is expected to more than double to USD 8.7 billion by 2034. This explosion tells a clear story: operational excellence isn't just a nice-to-have anymore; it's a competitive weapon.

At its core, mastering inventory and logistics is about making a promise to your customer—and having the operational backbone to keep it. It’s what turns a one-time buyer into a loyal fan for life.

For any D2C brand, getting this right is a game-changer. It means you can:

This guide will give you the strategies and tools to strike that perfect balance. To go even deeper, check out our detailed article on how logistics and inventory management combine to create an unbeatable operational system.

To really get a grip on the relationship between inventory management and logistics, you first need to speak the language. The industry is full of terms that can sound pretty intimidating, but they’re all built on simple, practical ideas. Let's break them down with some straightforward analogies, turning all that jargon into actual business wisdom you can use.

Think of it this way: managing your inventory is a lot like planning a road trip. You wouldn’t just hit the gas without checking the weather, knowing where the next rest stop is, or having a spare tire in the trunk. Each of those common-sense precautions has a direct parallel in your warehouse.

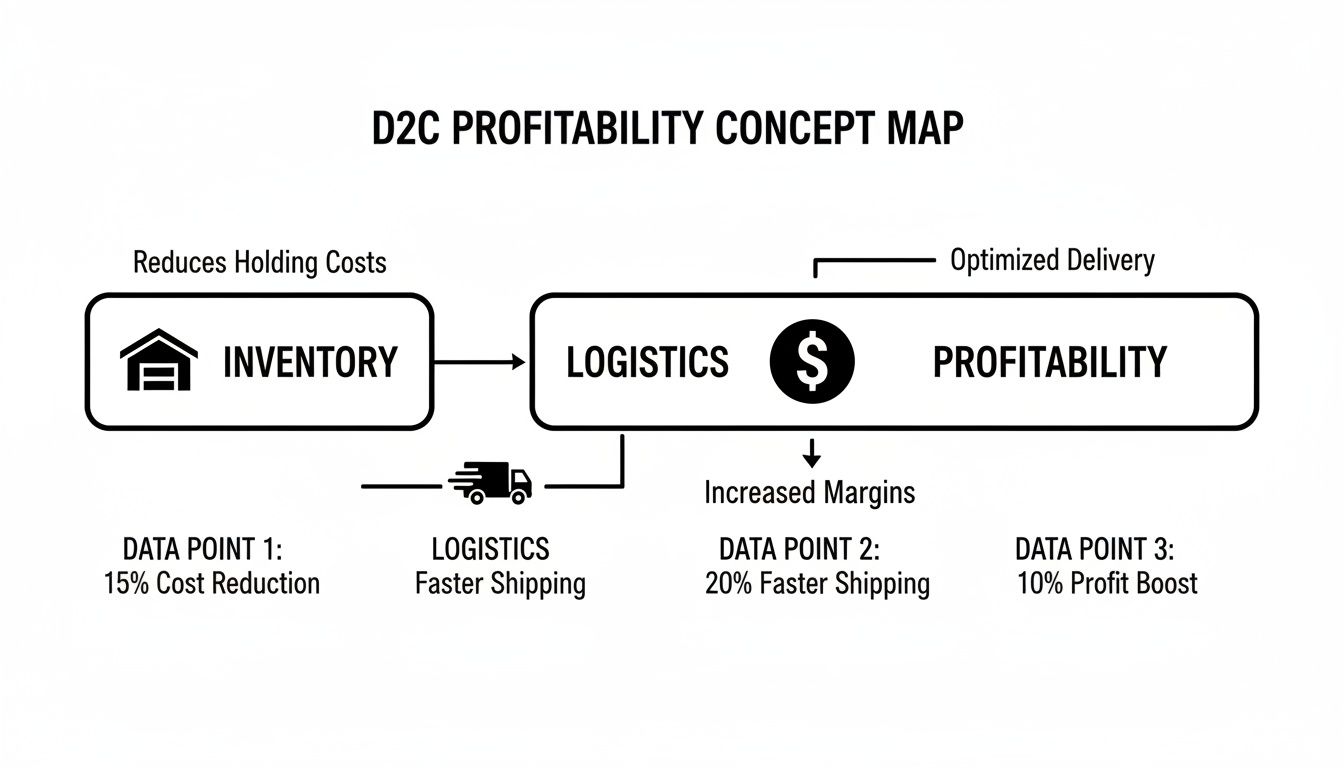

This chart shows just how tightly inventory and logistics are connected, and how getting them right directly fuels profitability for D2C brands.

It’s clear that managing what you have and moving it efficiently aren't two separate goals. They're two sides of the same profitability coin.

To help clarify these core ideas, here's a quick breakdown of the most important concepts you'll encounter.

| Concept | What It Is | Why It Matters For Your Store |

|---|---|---|

| Demand Forecasting | An educated guess about what customers will buy in the future, based on past data and current trends. | It’s your business’s weather report. It stops you from ordering winter coats in July or running out of bestsellers during Black Friday. |

| Safety Stock | A small, extra buffer of your most popular products kept on hand just in case of unexpected delays or sales spikes. | This is your emergency stash. It prevents stockouts when a supplier is late or a TikTok video goes viral, saving sales and keeping customers happy. |

| Reorder Point | The specific stock level that automatically triggers a new purchase order for a product. | Think of this as your "low fuel" light. It tells you exactly when to restock so new inventory arrives just before you run out, avoiding costly sales gaps. |

These terms aren't just academic—they are the building blocks of a resilient and profitable e-commerce operation. Let's dig a little deeper into how they work in the real world.

Demand forecasting is your business's weather report. Simple as that. Just like you'd check the forecast to decide between packing shorts or a raincoat, demand forecasting helps you predict what your customers will want to buy, and when. It’s all about looking at past sales data, current market trends, seasonality, and even your own marketing calendar to make an educated guess about what’s coming.

For instance, a D2C swimwear brand doesn't just look at last June's sales to plan for this summer. They're also factoring in things like:

Without this forward-looking perspective, you're driving blind. You’re almost guaranteed to run out of your best-sellers during peak season or get stuck with a warehouse full of unwanted stock.

Next up is safety stock. This is the spare tire for your business. You hope you don’t need it, but when a surprise pothole—like a supplier delay, a damaged shipment, or that unexpected influencer shoutout—threatens to stall your sales, it's an absolute lifesaver.

Safety stock is that extra cushion of inventory you hold specifically to prevent stockouts when things don’t go according to plan.

Holding too little safety stock leaves you vulnerable to lost sales and frustrated customers. But holding too much ties up cash in your warehouse that could be used for marketing, product development, or other growth initiatives.

Finding that sweet spot is the goal. For a fast-moving product with a super reliable domestic supplier, you might only need a tiny buffer. But for that unique item with a long, unpredictable lead time from an overseas factory, a larger safety stock is a smart investment to protect your revenue.

Finally, the reorder point is your car's fuel gauge. It's the pre-set inventory level that screams, "Time to order more!" When your stock on hand hits this number, it’s the signal to refuel before you run on empty and your sales engine sputters to a halt.

This isn't just a random number you pull out of thin air. A proper reorder point formula considers two critical pieces of information:

By combining your demand during that lead time with your safety stock level, you create a reorder point that ensures new inventory shows up right when you need it. This simple but powerful metric is the key to moving from reactive, panicked ordering to a smooth, automated, and stress-free replenishment cycle.

Numbers tell a story, but you have to know which ones to listen to. If you want to move past guesswork, Key Performance Indicators (KPIs) are your command center, giving you a real-time view of your inventory and logistics health. They turn a mountain of data into a clear story about what’s working, what's broken, and where your money is hiding.

Think of these metrics as vital signs for your business. A doctor wouldn’t diagnose a patient without checking their heart rate and blood pressure. In the same way, you can't fix your operations without tracking the core data that drives your cash flow and profits. Getting a handle on these KPIs is the first step toward making smart, data-driven decisions instead of just going with your gut.

Your Inventory Turnover Rate tells you how many times you sell through your entire stock over a set period, usually a year. It’s a direct measure of how efficiently your capital is working for you. A high turnover is like a busy restaurant that’s constantly flipping tables—cash flows in quickly, and nothing sits around getting stale.

A low turnover rate, on the other hand, is like a grocery store with wilting produce. It’s a huge red flag that your money is tied up in slow-moving items that are collecting dust instead of generating revenue. This leads to bigger storage bills and the risk of your products becoming obsolete.

Calculating it is straightforward:

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory Value

For any Shopify store, your COGS and inventory values are right there in your analytics reports, making this an easy metric to start tracking today.

While turnover gives you the big picture, Sell-Through Rate zooms in on how individual products are performing. It simply compares the number of units you sold to the number you received from your supplier in a given timeframe, usually a month. It’s the clearest signal you have for what’s a hit and what’s a miss.

Imagine you order 100 units of a new t-shirt design and sell 85 of them in the first month. That’s a fantastic 85% sell-through rate. You've got a winner. But if you only sold 15 units, that 15% rate is telling you to rethink your marketing or maybe even cut the product loose.

Tracking sell-through rate is your direct line to customer demand at the SKU level. It helps you pinpoint bestsellers that might need more safety stock and identify the slow-movers you should put on sale or bundle up.

Carrying Costs (or holding costs) are all the expenses that come with storing unsold inventory. This is the silent killer of profit margins because it's so much more than just the rent for your warehouse space.

These costs typically break down into four buckets:

As a rule of thumb, carrying costs can easily eat up 20% to 30% of your total inventory value. Let that sink in. For every $100,000 of inventory sitting on your shelves, you could be spending up to $30,000 a year just to keep it there. This reality check underscores just how critical solid inventory management and logistics are to your bottom line.

The urgent need to get these costs under control is fueling massive change. The global market for logistics automation is set to explode from USD 1,551.1 million in 2025 to USD 5,698.8 million by 2033. For D2C brands, getting on board with smarter systems isn't just an advantage—it's becoming a requirement for survival. You can dig into research about the explosive growth of logistics automation to see just how fast this space is moving.

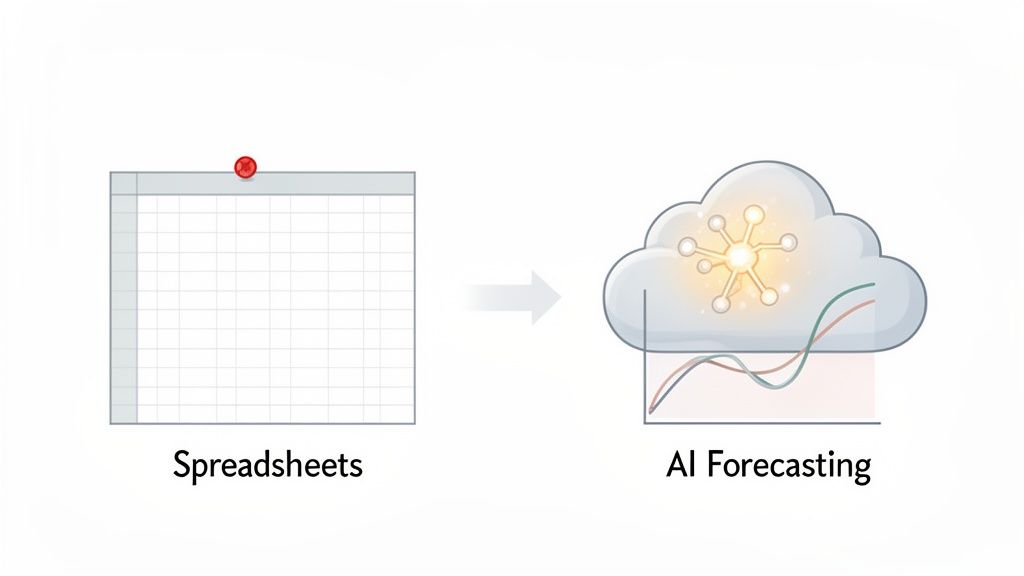

If you're still wrangling your business on spreadsheets, you're essentially trying to navigate today's hyper-competitive e-commerce market with a paper map. Sure, it’s familiar, but it’s also dangerously manual and riddled with errors that can quietly drain your profits. Sticking with static documents is a major bottleneck for modern inventory management and logistics.

The risks are bigger than you might think. Manual data entry is a minefield for human error—a single misplaced decimal can wreck an entire forecast, leading to frustrating stockouts or cash-eating overstock. Spreadsheets also live in the past; by the time you've crunched the numbers, the market has already sprinted ahead. Most importantly, they just can't keep up as your D2C brand grows.

The jump from scattered data to the clarity of AI-driven insights is a game-changer.

This isn't just an upgrade; it’s a fundamental shift from constantly putting out fires to proactively planning your next move. It’s about letting smart technology handle the heavy lifting so you can focus on building your brand.

The next chapter in inventory planning is being written by artificial intelligence. AI platforms go way beyond simple historical averages and fixed reorder points. They sift through mountains of data to spot complex patterns, seasonal quirks, and market shifts that no human—or spreadsheet—could ever catch. This makes intelligent tools a competitive necessity, not just a nice-to-have.

We're at a tipping point for AI adoption. Among small and medium-sized businesses, AI use is expected to more than double, jumping from 23% in 2024 to 48% in 2025. The reasons are incredibly practical: demand forecasting is set to lead the charge at 63% adoption, with inventory optimization right behind it at 58%.

Traditional forecasting often just looks at last year's sales to guess this year's demand. It's a decent starting point, but AI goes so much deeper. It weaves together a huge number of variables to paint a far more accurate and dynamic picture of what your customers are going to buy.

An AI model can analyze: * Historical Sales Data: Finding subtle patterns that go beyond simple monthly totals. * Seasonality and Trends: Understanding how holidays, weather, or cultural moments drive demand. * Promotional Calendars: Calculating the expected sales lift from your next marketing campaign. * External Factors: Even accounting for things like economic indicators or social media buzz that influence buying habits.

By processing all this in real-time, AI systems can adjust their forecasts on the fly. When a random TikTok trend sends sales for one of your products through the roof, the system sees it, learns from it, and updates its recommendations instantly. For a deeper look at the mechanics, check out our guide on modern demand forecasting software.

AI doesn't just report on what happened. It builds a sophisticated model to predict what is most likely to happen next, giving you a massive advantage in a fast-moving market.

One of the biggest headaches for D2C brands is finding the time to actually make sense of all their data. An intelligent analytics platform does the grunt work for you, automatically bubbling up critical insights that would take hours of manual digging to uncover.

Instead of you having to hunt through reports for slow-moving SKUs, an AI platform proactively flags them. It can pinpoint products with shrinking margins, show you which items are frequently bought together, and even recommend the perfect reorder quantities to maximize your return on investment.

This proactive approach to inventory management and logistics frees up an incredible amount of time and mental energy. It lets your team stop being data miners and start being strategic thinkers, acting on clear, data-backed recommendations. The end result is a smarter, more resilient business that can pivot quickly, no matter what comes next.

Even the sharpest brands stumble. But in the world of inventory management and logistics, a small misstep isn't just a minor headache. It's a costly error that eats into your profits, tarnishes your reputation, and can send your hard-won customers straight to the competition. Getting a handle on these common pitfalls is the first real step toward building an operation that’s built to last.

So many of these problems start small and then snowball. A single typo in a spreadsheet can set off a chain reaction, leading to overselling a hot product and dealing with a flood of angry customer service tickets. The goal is to shift from a reactive, "firefighting" mode to a proactive strategy that sees these risks coming and neutralizes them before they can do any damage.

Let's walk through the most frequent and damaging inventory blunders and—more importantly—the practical ways you can dodge them for good.

One of the most classic inventory mistakes is misjudging seasonal demand. Picture a fashion brand sitting on a mountain of heavy winter coats in July. They didn’t anticipate the steep drop-off in demand as temperatures rose, and now their cash is frozen in products that won’t move for another six months. This forces them into deep, margin-killing discounts just to free up space and capital.

And this isn't just an apparel problem. From a surge in sunscreen sales every spring to a spike in gift baskets during the holidays, almost every D2C business has some kind of seasonal rhythm. Pretending it doesn't exist is a recipe for disaster.

How to get in sync:

Your entire operation is built on the foundation of your inventory data. If that data is wrong, every single decision you make—from placing purchase orders with suppliers to launching a new marketing campaign—is fundamentally flawed. This usually boils down to manual entry errors, systems that don't talk to each other, or simply not doing regular physical stock counts.

The fallout is brutal. Inaccurate data creates phantom inventory (showing you have stock when you don't) and hidden inventory (having stock you don't know about). This leads directly to overselling, stockouts, and a total erosion of trust with your customers.

A single source of truth for your inventory data isn't a "nice-to-have." It's the absolute bedrock of a stable e-commerce business. Without it, you're flying blind.

You can have the most perfect demand forecast in the world, but it can be completely shattered by one unreliable supplier. If you plan for a two-week lead time but your supplier consistently takes four, you're going to be constantly sold out of your best products. Your inventory management and logistics are only as strong as the weakest link in your supply chain.

Too many brands get fixated on the unit cost from a supplier and ignore other critical performance metrics. Late deliveries, inconsistent quality, and poor communication will cost you far more in the long run than you’d ever save with a slightly lower price point.

How to build a more resilient supply chain:

By getting ahead of these common mistakes, you can turn your operations from a constant source of stress into a powerful competitive advantage that fuels your growth.

Let's be honest, all the theory in the world doesn't mean much until you put it into practice. This is where the rubber meets the road. We're going to take everything we've talked about—from inventory management to logistics—and boil it down into a simple, actionable roadmap.

Think of this as your starting point. Don't try to do it all at once. Just pick one or two things from this list, get a win under your belt, and build from there. These small, consistent changes are what create a truly resilient and profitable brand.

Audit Your SKU Performance by Profit Margin.

Calculate Safety Stock for Your Top 10 Bestsellers.

Automate Your Low-Stock Alerts.

Schedule a Quarterly Inventory Health Review.

Review and Verify Supplier Lead Times.

Remember, the goal here is progress, not perfection. Mastering these processes is a journey, and taking these initial steps puts you firmly on the right path.

As you build these habits, you might want to bring in a formal framework. Using an audit and compliance checklist for transportation and logistics during your reviews can help you spot potential issues before they become expensive problems.

And if you're ready to go even deeper on making your stock work smarter for you, our guide to inventory optimization techniques is the perfect next step. Each of these actions builds on the last, creating a powerful system for sustainable growth.

Even with the best strategy, you're going to have questions. Getting straight answers to the everyday hurdles of running a D2C brand can be the difference between a minor hiccup and a major headache. Let's tackle some of the most common questions we hear from founders about inventory and logistics.

Think of this as a quick-reference guide to help you turn theory into confident, practical action.

This is the classic debate, and honestly, the right answer depends on your scale. You've got two main camps: the big annual count and the more modern cycle counting.

The annual, wall-to-wall count is that old-school approach where you literally shut everything down for a day or two and count every last widget.

Then there's cycle counting. This is a much smarter, more agile way to operate. Instead of one huge, disruptive event, you're continuously counting small, specific sections of your inventory on a rotating schedule. You might, for example, count your top 20% of SKUs every month and your slower-moving items just once a quarter.

Cycle counting turns inventory accuracy from a once-a-year fire drill into a consistent, ongoing operational habit. It's about catching and fixing small errors fast, with almost no disruption to your day-to-day.

For nearly every D2C brand, cycle counting is the clear winner. It keeps your data clean all year round, slashes operational downtime, and makes it way easier to spot the root cause of a problem before it spirals out of control.

If your current forecasting method is mostly just a gut feeling, the single most powerful first step you can take is to get your historical sales data in one place. Seriously, that's it. Your past performance is the bedrock of any decent forecast. Before you even think about fancy software or complex models, you need a clean, organized dataset.

Start by pulling your sales data from every channel—Shopify, Amazon, wholesale, wherever you sell—into a single spreadsheet or database. For at least the last 12-24 months, you need to capture a few key things:

Once you have this baseline, you'll be amazed at the patterns that jump out. This simple step is what moves you from guessing to making genuinely data-informed predictions.

It’s easy to look at the price tag and flinch, but that's framing the question the wrong way. It's not about the cost; it's about the return on investment (ROI). Enterprise-level systems are overkill, sure, but the market is now filled with powerful, AI-driven platforms built specifically for brands like yours.

The real question is: can you afford to keep doing things manually?

Think about the hidden costs you're already paying: * Lost Sales from stocking out of your best-selling product. * Tied-Up Capital in a pile of slow-moving inventory that's just collecting dust. * Wasted Time—those hours every week your team spends wrestling with spreadsheets could be spent on growing the business.

Modern inventory tools often pay for themselves surprisingly fast by plugging these financial leaks. Industry studies show that AI-powered inventory operations can slash excess inventory by up to 30% and cut logistics costs by as much as 20%. For a growing brand, that’s not just an efficiency gain; it’s a huge injection of cash you can put right back into marketing and product development.

Ready to stop guessing and start planning with confidence? Tociny.ai provides AI-powered inventory analytics to give you a clear view of your sales, predict future demand, and offer actionable recommendations to reduce stockouts and eliminate overstock. Get early access and see how our platform can support your profitable growth at https://tociny.ai.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.