Logistics inventory management is all about getting your products where they need to go, efficiently and profitably. It’s the art and science of coordinating the physical movement of your goods (that’s the logistics part) with the smart, data-driven control of your stock levels (the inventory management part).

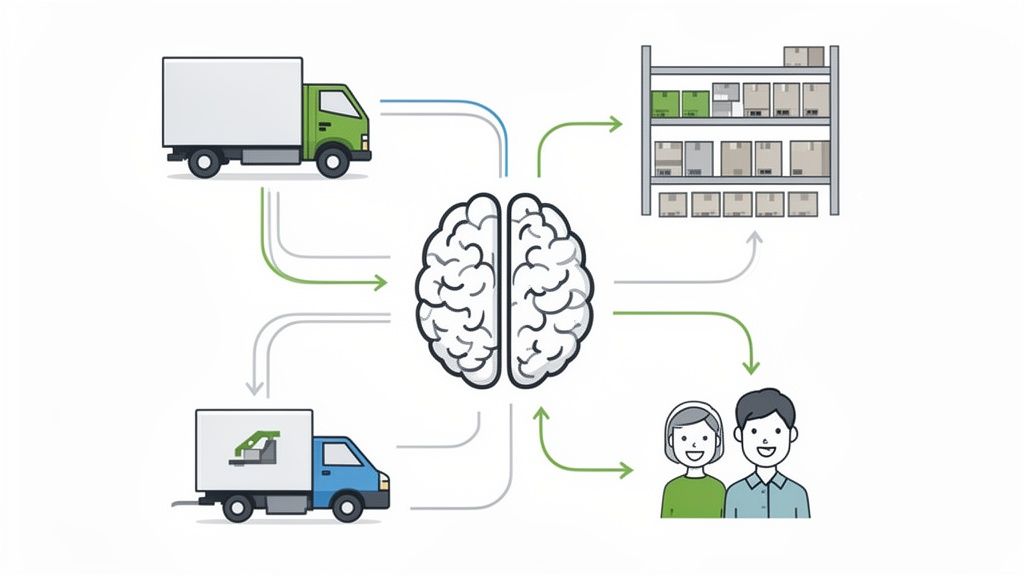

Think of it as the brain of your entire D2C operation, making sure the right product is in the right place, at the right time, without costing you a fortune.

For any Shopify or D2C brand trying to scale, getting a handle on this isn't just another task on the to-do list—it's your secret weapon. When it’s running smoothly, your products glide from supplier to warehouse to your customers' doorsteps. It’s a beautiful, profitable journey.

But when it breaks down? Total gridlock. You end up with stockouts on your bestsellers, which means frustrated customers and lost sales. At the same time, you’ll have cash tied up in products that aren't selling, just sitting on a shelf collecting dust and eating away at your profit margins.

To really nail this, you have to understand that you're juggling two distinct but deeply connected disciplines. Get both right, and you're golden.

You can have the fastest shipping on the planet, but if your inventory management is a mess, you'll still be plagued by stockouts. On the flip side, even the most brilliant demand forecast is useless if your logistics can't get the product where it needs to be. For D2C brands, this is especially critical, helping you dodge the common pitfalls explained in this guide to understanding the tricky challenges of inventory management.

Let's be honest, today's e-commerce world is chaotic. Customer demand swings wildly, supply chains get disrupted overnight, and operating costs are always climbing. Flying blind or just guessing is no longer a viable strategy.

The ability to adapt quickly is everything. Modern inventory management gives you the power to scale your logistics in real-time, turning what used to be a fixed cost into a flexible, operational advantage.

The market is clearly catching on. The logistics automation space, specifically the inventory management segment, was valued at a huge USD 1,551.1 million in 2025 and is expected to explode to USD 5,698.8 million by 2033. This boom shows just how many brands are turning to smarter, AI-powered tools to wrestle back control of their operations.

Ultimately, mastering these concepts shifts your brand from being reactive—constantly putting out fires—to being proactive. You can start planning for growth, protecting your margins, and building the kind of loyal customer base that every brand dreams of. You can dive deeper into the fundamentals in our comprehensive guide to inventory management.

To truly get a handle on your inventory, you have to stop seeing it as a number in a spreadsheet. Instead, think of it as a complete journey. This journey has four distinct stages that act as the pillars of a rock-solid workflow. When you dial in each one, you create a seamless operation that runs efficiently and protects your profit margins.

Think of it like a relay race. A strong start in receiving sets up a smooth handoff to warehousing. That, in turn, enables a lightning-fast fulfillment leg, leading to a clean finish with returns. If any single runner drops the baton, the whole race is in jeopardy.

Let's break down each pillar and see how they fit together in a modern D2C brand.

To put it all into perspective, here’s a quick overview of each stage, its primary goal, and a common hurdle that growing D2C brands face.

| Workflow Stage | Primary Goal | Common Challenge for D2C Brands |

|---|---|---|

| Strategic Receiving | Ensure 100% accuracy from the moment stock arrives. | Manual data entry errors leading to phantom stock. |

| Intelligent Warehousing | Organize stock for maximum picking speed and efficiency. | Disorganized storage that increases walk times for staff. |

| Optimized Fulfillment | Pick, pack, and ship orders as quickly as possible. | Inefficient pick paths and packing station bottlenecks. |

| Seamless Returns | Get resellable items back into active inventory immediately. | Slow processing that ties up capital in returned goods. |

Nailing each of these goals is the key to building an inventory system that doesn't just keep up with your growth but actively drives it.

This is your first—and best—line of defense against inventory chaos. Strategic receiving isn't just about unloading boxes off a truck. It's about accurately and efficiently getting new stock into your system so it's ready to sell. An error here, like miscounting items or scanning the wrong SKU, can create phantom stock issues that will haunt you for months.

For any growing Shopify brand, the objective is to make this process as foolproof as possible.

When you nail your receiving process, you ensure that from the second inventory enters your building, your data is 100% accurate. This is the non-negotiable first step.

Okay, the inventory is received and accounted for. Now, where does it go? Intelligent warehousing is the art of organizing your products for one main purpose: speed. It’s not about just finding an empty shelf; it’s about strategically placing items to slash the time it takes your team to find them when an order drops.

Think of your warehouse like a well-organized library. The most popular new releases are kept right near the front desk for quick access, while obscure academic texts are stored in the back. Applying that same logic to your best-selling products can dramatically cut down on picking times.

This is where a Warehouse Management System (WMS) becomes a total game-changer. It acts as the brain of your physical storage space, optimizing where things go and tracking every item's location so nothing gets lost in the shuffle. For D2C brands, this translates directly to faster order processing, fewer misplaced items, happier customers, and lower operational costs.

This is the stage where all your careful planning pays off. Optimized fulfillment covers everything from picking items off the shelf to packing them securely and getting them out the door. How efficient you are here is critical for meeting customer expectations for fast, accurate delivery—the new standard in e-commerce.

A poorly organized pick path, for example, can have your team walking unnecessary miles every single day. Those extra steps add precious minutes to every order, killing your efficiency.

Here are a couple of quick wins for optimization:

The smoother your fulfillment process, the quicker you get products into your customers' hands. In today's market, that’s a massive competitive advantage.

The final pillar—and one that's too often an afterthought—is returns. Also known as reverse logistics, a smooth returns process is absolutely vital for protecting your profits and maintaining customer trust. A clunky, slow, or confusing returns experience can turn a loyal customer away for good.

Your goal here is simple: get resellable items back into your active inventory as quickly as humanly possible. This means inspecting returned goods, updating your stock levels accurately, and processing refunds promptly. A well-defined workflow prevents returned items from piling up in a corner and ensures your inventory data remains pristine, closing the loop on excellent logistics inventory management.

Profit leaks often hide in plain sight within your inventory data. The numbers that separate thriving D2C brands from the ones just getting by aren't always on the main balance sheet; they’re buried in the day-to-day operational metrics. Figuring out these numbers is what gives you the clarity to plug financial drains and start making much smarter decisions.

Getting a handle on logistics inventory management is really about turning abstract data into real-world action. If you're not tracking the right metrics, you’re flying blind. You can't see the small, subtle inefficiencies that are quietly eating away at your profits, day after day.

One of the most overlooked expenses for any D2C brand is carrying cost. The easiest way to think about it is as the "rent" your unsold products pay just for the privilege of sitting on a warehouse shelf. But it’s more than just storage fees. It’s a whole bundle of expenses that includes insurance, the risk of damage or obsolescence, and the capital you have tied up in stock that could be working for you somewhere else.

This isn't just some minor line item; it directly eats into your margins. To get a real sense of this hidden cost, it's worth digging into a full breakdown of what inventory carrying cost includes and how to calculate it for your business. The higher your carrying costs, the more pressure you're under to move product—fast.

To really gain control, you need to keep your eyes on a handful of critical metrics. These are the vital signs of your inventory’s health, telling you exactly where your operations are strong and where they’re bleeding cash.

When you consistently track these numbers, you stop making gut-feel decisions and start executing a precise, profitable strategy. The data doesn't lie; it points you exactly where you need to focus your attention for the biggest impact.

These metrics are your early warning system for the three biggest financial threats to any D2C store. When your numbers are off, you inevitably fall into one of these expensive traps.

These challenges have only gotten tougher in recent years. The Logistics Managers' Index (LMI) recently pointed to a major surge in inventory-related expenses, with Inventory Costs hitting a painful 79.2 in August 2025. This was felt even more acutely by downstream firms like D2C brands, which reported costs at 79.2 versus upstream's 73.3. At the same time, warehousing prices stayed high, showing just how much financial pressure is mounting on brands. You can learn more about these recent logistics trends and cost increases to see the bigger picture.

Knowing which metrics to track is the easy part. Turning that insight into action? That's where real growth happens. Think of this section as your step-by-step playbook for taking back control of your stock and building a much more profitable operation. It’s a clear, progressive path designed for growing D2C brands to start using immediately.

The goal isn't to flip your entire operation on its head overnight. Instead, we'll walk through a series of deliberate, high-impact steps. Each one builds on the last, creating lasting change in your logistics inventory management strategy.

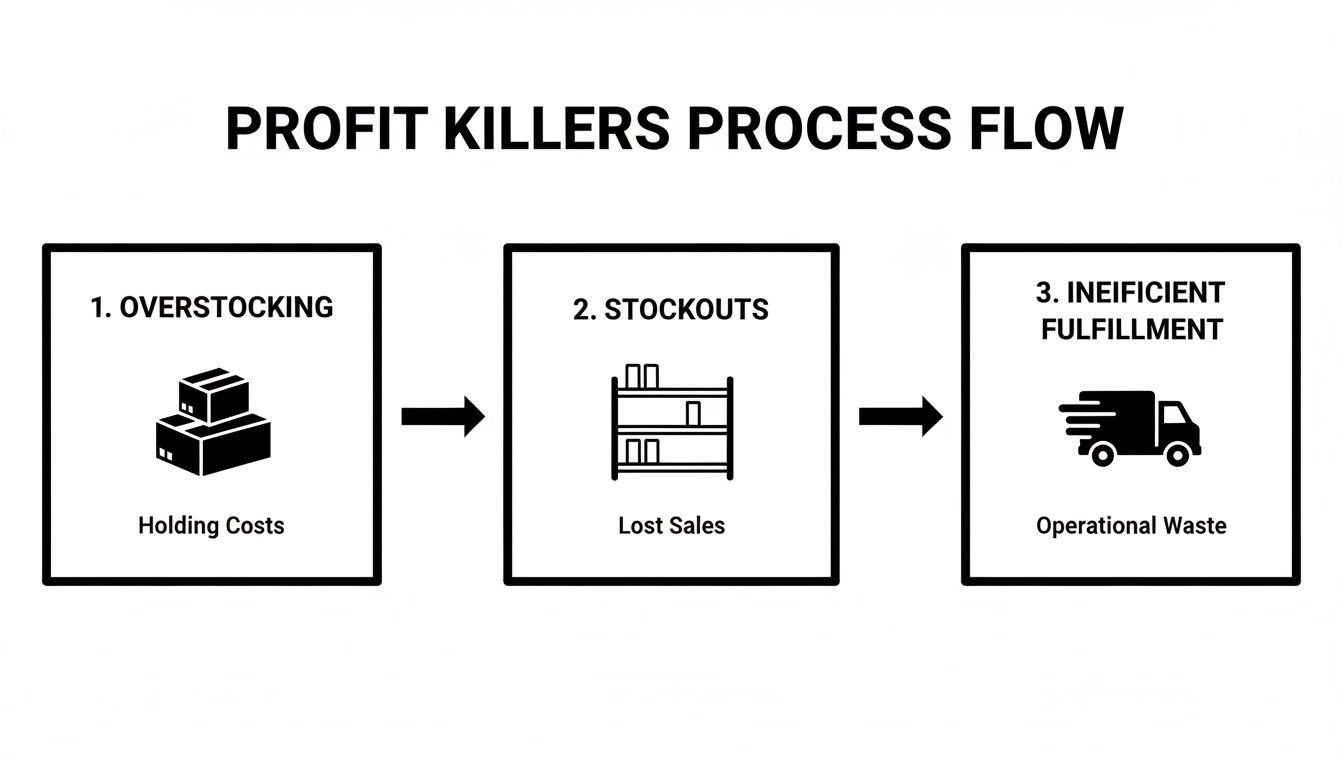

This flowchart maps out the most common profit killers that a solid inventory system helps you dodge.

Every one of these issues—overstocking, stockouts, and inefficient fulfillment—is a direct hit to your margins. The good news is they are all completely solvable with the right plan.

Let's be honest: not all of your products are created equal. The Pareto Principle (or the 80/20 rule) is almost always in play here: roughly 20% of your SKUs are likely driving 80% of your revenue. An ABC analysis is a straightforward way to group your products based on how much value they bring to the table.

By sorting your inventory this way, you can finally stop treating every single product the same. Your 'A' items demand tight control, frequent monitoring, and careful forecasting to never, ever stock out. On the flip side, your 'C' items can be managed with a lighter touch, maybe with lower stock levels to free up cash and warehouse space.

Once you know which products matter most, the next move is making sure you never run out of them. A reorder point (ROP) is simply the stock level that triggers you to order more. Getting this number right is a delicate balancing act between preventing stockouts and avoiding a warehouse full of cash-draining excess inventory.

To calculate it, you just need two key figures:

Figuring this out manually for every SKU is a soul-crushing task. This is the exact point where basic tools start to break down and hold your brand back from scaling its logistics inventory management.

For a tiny brand with a handful of products, a spreadsheet feels like it's enough. But as you grow, that spreadsheet quickly becomes your biggest liability. It's a minefield of human error, has no real-time data, and offers zero predictive power. Trying to manually track sales velocity and supplier lead times for dozens—let alone hundreds—of SKUs is a recipe for disaster.

Moving to a centralized inventory platform isn't just an "upgrade." It's a fundamental shift from reactive guesswork to proactive, data-driven decision-making. These systems become the single source of truth for your entire operation.

A dedicated platform automates all the tedious calculations for reorder points and safety stock. It can plug directly into your sales channels, like Shopify, giving you a live, accurate picture of your inventory at all times. For any D2C brand serious about professionalizing its operations, this move is non-negotiable.

An inventory strategy should never be "set it and forget it." Market trends change, customer tastes evolve, and supplier performance can be unpredictable. The final, ongoing step in this roadmap is to build a rhythm of continuous improvement.

Put a recurring meeting on the calendar—monthly or quarterly—to dive into your performance data.

This cycle of analysis and refinement turns your logistics inventory management from a static task into a dynamic system that adapts and grows with your business. It’s how you consistently optimize for profit and get ahead of problems before they can ever hurt your customer experience.

Jumping into a full optimization project can feel daunting. The good news is that you don't have to do everything at once. Here are some quick wins you can implement at each stage to see an immediate impact.

| Optimization Stage | Quick Win Action Item | Expected Benefit |

|---|---|---|

| Step 1: ABC Analysis | Identify your top 5 'A' SKUs and your bottom 10 'C' SKUs. | Instantly focus your attention where it matters most and identify capital tied up in slow-movers. |

| Step 2: Reorder Points | Manually calculate and set a basic reorder point for just your top 5 'A' SKUs. | Dramatically reduce the risk of stocking out on your most profitable products. |

| Step 3: Beyond Spreadsheets | Start a free trial with an inventory management platform to sync your sales data. | Gain immediate visibility into real-time stock levels and sales velocity without full commitment. |

| Step 4: Review & Refine | Schedule a 30-minute meeting next month to review the performance of your top 5 SKUs. | Build the habit of data review and start making small, informed adjustments. |

These small actions create momentum. By focusing on high-impact, low-effort tasks first, you can start building a more resilient and profitable inventory system right away.

Let's be honest: the old way of managing inventory is officially over. For years, forecasting meant looking at last year's sales, adding a bit of guesswork, and hoping for the best. It's like trying to drive forward while staring exclusively in the rearview mirror—it shows you where you've been, but it’s a terrible guide for what’s ahead.

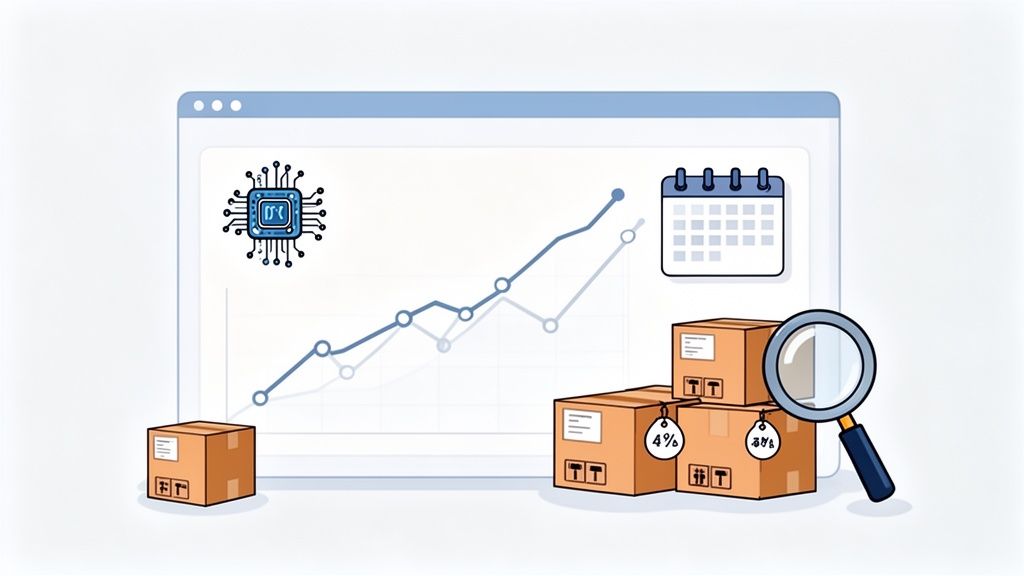

Now, technology—specifically artificial intelligence (AI)—is turning this reactive chore into a predictive science. Think of it like a hyper-accurate weather forecast, but for your sales. Instead of just rehashing old data, AI models dig into a ton of complex variables: seasonality, new market trends, your upcoming promo schedule, and even what your competitors are charging, all to predict future demand with startling accuracy.

This isn't about replacing human gut feelings; it's about backing them up with serious data firepower. The goal is to shift the conversation from "What did we sell last year?" to "What are customers actually going to buy next month, and why?"

This kind of sophisticated analysis gives brands a bird's-eye view of their entire logistics and inventory world, connecting the dots in ways that would be flat-out impossible for a human to spot alone.

This digital shift in logistics is completely changing how D2C brands think about their stock. The market for these smart logistics tools is expected to hit $46.5 billion by the end of 2025, rocketing up at a 21% CAGR. What's driving this? A massive adoption of AI and real-time analytics. In fact, 77% of warehousing leaders now say these technologies are essential, and the use of predictive tools is set to grow by 36%. This is exactly why platforms that bake in this tech are giving Shopify merchants a huge leg up.

This change means brands can finally get out in front of problems. Instead of waiting for a bestseller to sell out before frantically reordering, AI can flag that you're running low weeks or even months ahead of time.

This proactive approach flips the script, turning your inventory from a cost center into a dynamic, profit-driving machine.

Not long ago, this kind of predictive power was a luxury reserved for massive corporations with their own data science departments. That's not the case anymore. Today, platforms are putting these tools directly into the hands of D2C brands with intuitive dashboards and clear, simple reports. They do all the heavy lifting behind the scenes.

The real magic of AI in inventory management isn't just the fancy algorithms. It's how it translates all that complexity into simple, actionable insights that anyone on your team can understand and use.

This is a massive equalizer. Now, you can make inventory decisions with the same confidence as your biggest competitors, dodging overstocks, wiping out stockouts, and freeing up your cash flow. If you're curious about the nuts and bolts, our guide on how AI demand forecasting works breaks it all down.

Of course, even with powerful AI, a solid grasp of the basics is still crucial. Understanding the fundamental methods to forecast demand gives you a foundation that makes these advanced tools even more effective. When you combine that foundational knowledge with AI-driven insights, you build a resilient and seriously profitable logistics inventory management system that's ready for whatever the market throws at it.

Even with a solid plan, you're bound to have questions as you start dialing in your inventory logistics. Here are some of the most common ones we hear from brands that are scaling up, with straightforward answers you can put to work right away.

Relying solely on a once-or-twice-a-year full physical count is an old-school move that leaves you vulnerable. Today’s sharpest brands run a hybrid model. The real game-changer is cycle counting, especially for your most valuable products.

Instead of shutting everything down for a massive, disruptive count, you count small, specific batches of products continuously—daily or weekly. Focusing on your high-value (Class A) items this way helps you catch issues like theft or damage almost as they happen. It makes that big year-end count way faster and a whole lot more accurate. Ultimately, the goal is to get to a point where your inventory management system gives you live data, so you don't even need to lean on manual counts.

It’s incredibly common to mix these two up, but knowing the difference is key to running a tight ship.

Picture your business as a library.

Bottom line: Inventory management is about knowing what you have, while logistics is about how it moves. For a D2C brand, you can't have one without the other; they have to work in perfect harmony.

Look, everyone starts with spreadsheets. For a brand with just a few products, it's totally fine. But you will outgrow them, and it will happen much, much faster than you think. Spreadsheets are a magnet for human error, they're never updated in real-time, and they have zero ability to tell you what's coming next.

A spreadsheet shows you where your inventory was yesterday. An analytics platform shows you where it needs to be tomorrow.

Once you’re managing dozens of SKUs, manually tracking sales velocity, lead times, and reorder points becomes a recipe for disaster. You’ll either run out of your bestsellers or burn cash on products that just sit there. This is the point where investing in a dedicated inventory analytics platform stops being a "nice-to-have" and becomes a necessity for making profitable decisions.

These are two opposing philosophies on how much stock to hold, and each has its place.

So, which is right for your D2C brand? For most, it's a mix of both. You can absolutely use JIT for products with super predictable demand and rock-solid suppliers. But for your A-list bestsellers or items from suppliers with shaky lead times, you’ll want a JIC safety buffer. The only way to find that perfect balance for each SKU is with solid forecasting tools that help you protect sales without tying up too much capital.

Ready to stop guessing and start making data-driven inventory decisions? Tociny.ai provides the AI-powered analytics and clear forecasting that Shopify brands need to reduce stockouts, eliminate overstock, and grow profitably.

Get early access and see how Tociny.ai can optimize your inventory

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.