Stock replenishment is simply the process of refilling your inventory. It’s about moving products from a backroom or warehouse to your primary picking shelves, or more often, ordering new stock from your suppliers to keep up with customer demand.

At its heart, it’s about getting the right product in the right place at the right time. Get it right, and you prevent lost sales and keep customers happy. Get it wrong, and you're either telling people you're sold out or drowning in unsold goods.

Think of your store’s inventory like the food in your kitchen pantry. You don’t wait until the coffee canister is completely empty to add it to your shopping list. You see it getting low and plan to buy more before that dreaded caffeine-free morning happens.

Stock replenishment is that exact same idea, just applied to your D2C brand. It’s the disciplined practice of restocking your inventory so you can always fulfill customer orders without a hitch.

The whole game is a balancing act. On one side, you have stockouts—the digital equivalent of an empty shelf. This means lost sales and, worse, frustrated customers who might just click over to your competitor. On the other side is overstock, where your cash is tied up in products that are just sitting there, racking up storage costs and risking becoming obsolete.

For any direct-to-consumer brand, mastering replenishment isn't just a boring operational task. It's a critical strategy for survival. A single "out of stock" notification can send a once-loyal customer away for good.

Effective replenishment has a direct ripple effect across your entire business:

The real challenge of inventory isn't just ordering more stuff. It's about ordering the optimal amount at the precise moment it's needed. This is how you turn inventory from a reactive headache into a proactive, profit-driving asset.

A well-oiled replenishment system gets you out of reaction mode—no more frantic, last-minute orders when a bestseller runs dry. Instead, you're running a proactive, data-driven operation. It's the foundation that supports everything else.

To really nail this, you need to understand the push-and-pull forces at play. Here's a quick breakdown of the core challenges every merchant faces.

This table sums up the tightrope walk that is inventory replenishment. Every decision is a trade-off between serving customers perfectly and keeping costs in check.

| Challenge | Negative Outcome | Goal of Replenishment |

|---|---|---|

| Stockouts (Understocking) | Lost sales, frustrated customers, and a damaged brand reputation. | Ensure consistent product availability to meet customer demand. |

| Overstocking | Tied-up capital, high storage costs, and the risk of dead stock. | Minimize holding costs and improve cash flow. |

| Supply Chain Delays | Unpredictable stock levels, leading to stockouts or panicked over-ordering. | Build a resilient system that accounts for supplier lead times. |

Ultimately, your replenishment strategy is your playbook for navigating these challenges. It’s how you ensure you have enough inventory to satisfy demand without letting your warehouse turn into a product graveyard.

Once you've got a handle on the delicate balancing act of stock management, it’s time to pick a specific method for your replenishment of stocks. Think of these models as different playbooks for the same game. Each has its own rules, strengths, and ideal situations. Picking the right one transforms your inventory process from a reactive scramble into a proactive, strategic operation.

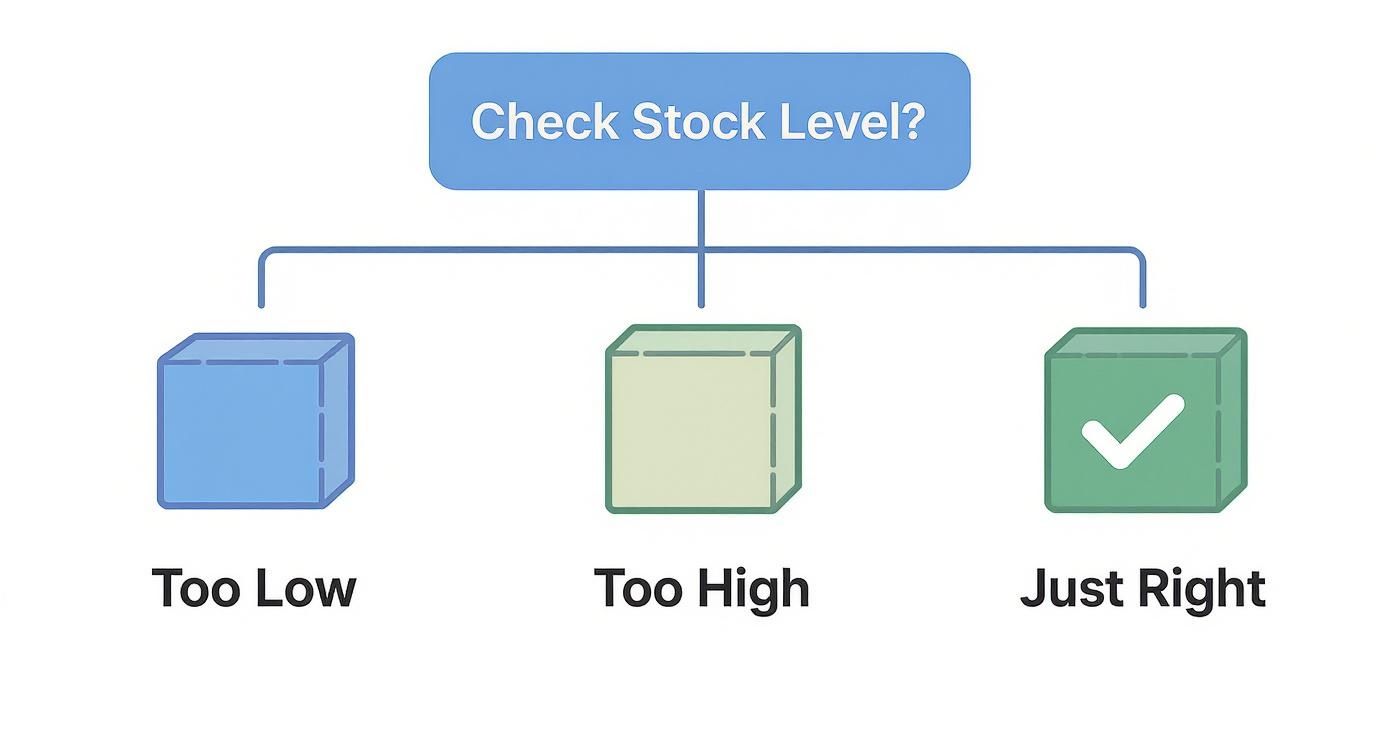

Moving from pure guesswork to a structured model is the secret to consistency. This simple decision tree shows the basic logic you'll apply every time you check your stock levels.

The goal, no matter which model you choose, is to keep your inventory in that "Just Right" sweet spot. You want to avoid the costly extremes of having way too little or far too much.

The Reorder Point (ROP) model is basically the low-fuel warning light in your car. It doesn't tell you to get gas every Monday morning; it alerts you when the tank hits a specific, predetermined level. In inventory terms, you place a new order only when your stock for an item drops to its designated reorder point.

This method is beautifully simple and works wonders for products with relatively stable demand. The formula is straightforward: (average daily sales × lead time in days) + safety stock.

In contrast to ROP, the Periodic Review model is more like your weekly grocery run. You don't check the pantry every single day. Instead, you check it at a fixed time—say, every Saturday morning—and buy what you need to restock for the week ahead.

With this approach, you review your inventory levels at fixed intervals (weekly, bi-weekly, or monthly) and place an order to bring your stock up to a desired maximum level.

This model simplifies purchasing by consolidating orders into a predictable schedule. Instead of placing small, sporadic orders, you create one larger purchase order for multiple products at the same time, which can streamline supplier relationships and potentially reduce shipping costs.

This method is perfect for businesses that want a predictable ordering schedule or work with suppliers who have specific ordering windows.

The Economic Order Quantity (EOQ) model is all about finding the perfect order size to minimize your total inventory costs. It directly answers the question: "How much should I order at once?" Ordering too little means you're constantly paying for shipping, but ordering too much leads to high holding costs that tie up your cash.

EOQ helps you find the sweet spot between these two expenses. For D2C merchants, this is about finding the most cost-effective order size for each product. To get into the nitty-gritty, you can learn more about what Economic Order Quantity is and see how the math works out.

Finally, we have the Just-in-Time (JIT) model, the ultimate lean approach to inventory. Imagine a sushi chef who gets fresh fish delivered exactly when needed for the evening service—no earlier, no later. JIT works the same way: inventory arrives from your supplier precisely when it's needed for production or to ship out to a customer.

This model aims to eliminate inventory holding costs almost entirely. The catch? It requires an extremely reliable and responsive supply chain, as any delay can cause an immediate and painful stockout.

Effective stock replenishment isn’t about gut feelings or lucky guesses; it’s powered by a smart engine that can predict the future. That engine is demand forecasting, the process of using data to estimate what your customers will want to buy, and when. It’s what turns inventory management from a reactive scramble into a proactive strategy.

Think of it like planning a road trip. You wouldn’t just glance at the gas gauge and start driving. You’d consider how far you're going, the terrain ahead, and your car's fuel efficiency. In the same way, smart replenishment looks far beyond your current stock levels.

To build a reliable forecast, you need to analyze a few key ingredients. Each one adds a critical piece to the puzzle, helping you see the full picture of what’s coming.

A forecast that ignores seasonality and lead times is like a weather report that only looks at yesterday's sky. It might be right by chance, but you're going to get caught in the rain more often than not. Real accuracy comes from weaving these data points together.

Getting these components right is the first step, but even the best forecasts have to contend with uncertainty. That’s where your inventory’s insurance policy comes into play.

Safety stock is the extra inventory you hold as a buffer against the unexpected. It’s your business's emergency fund, protecting you from sudden demand surges—like a product going viral on TikTok—or frustrating supplier delays.

Without safety stock, a small hiccup can cause a complete stockout, costing you sales and damaging customer trust. The good news is, calculating it doesn't have to be rocket science. Here’s a simple, step-by-step example for one of your products:

This result tells you to keep 450 units on hand as a buffer. While manual calculations like this get the job done, modern tools offer a much sharper edge.

Manual forecasting has its limits. It often relies on simple averages and can easily miss the complex, subtle patterns hiding in your sales data. This is where AI-driven platforms like Tociny.ai completely change the game.

Intelligent forecasting tools don't just look at averages; they analyze thousands of data points at once. They can spot hidden trends, correlations, and anomalies that are impossible for a human to see. They can automatically weigh recent sales spikes more heavily or factor in external events like holidays or marketing campaigns, leading to far more precise predictions.

This precision has a direct impact on your safety stock. With more reliable forecasts, you can stop relying on huge "just-in-case" inventory buffers. You end up holding less excess stock, which frees up a ton of cash, while still being better protected against stockouts. For a deeper look into the mechanics, our guide on demand forecast methods breaks it down even further.

Ultimately, AI transforms forecasting from a backward-looking report card into a powerful, forward-looking competitive advantage.

You can't improve what you don't measure. Setting up a smart replenishment of stocks strategy is a great start, but the real power comes from tracking its performance. Without the right metrics, you’re just flying blind, completely unable to tell if your inventory decisions are boosting profits or quietly draining your bank account.

Think of these key performance indicators (KPIs) as the vital signs of your business's health. They’re not just numbers to fill up a dashboard; they tell you what's working, what's broken, and exactly where your biggest opportunities for improvement lie.

To get a clear, honest picture of your inventory health, you need to zero in on a few core metrics. Each one gives you a different lens through which to view your operational efficiency and, ultimately, your profitability.

Let's break down the most critical ones:

These metrics don't live in a vacuum; they work together to tell a complete story. For instance, a high inventory turnover looks great on paper, but not if it’s causing a sky-high stockout rate because you’re constantly under-ordering. It’s all about balance.

Beyond just tracking sales and availability, you have to get real about the true price of the inventory you hold. This is where Carrying Costs come into play. This metric lumps together all the expenses tied to storing unsold goods—think warehousing fees, insurance, labor, and the cost of capital that’s just sitting there, tied up in that stock.

It often comes as a shock to business owners, but carrying costs can easily add up to 20-30% of an inventory's total value each year. Facing this number forces you to be way more strategic about how much stock you actually need.

The goal isn’t just to have products on the shelf; it’s to have the right amount of the right products. Inefficient replenishment leads to bloated inventory, and that inventory quietly eats away at your profits every single day it sits unsold.

This isn’t just a small-business problem; it's a global one. According to the Netstock 2025 Benchmark Report, a staggering 17% of businesses report that over a tenth of their inventory has been gathering dust for more than a year. These findings highlight a massive, widespread issue with dead stock and underscore just how urgently businesses need better replenishment strategies. You can discover more insights on supply chain planning by reviewing the full report.

Let’s make this real. Imagine a Shopify store owner notices their Inventory Turnover Ratio for a specific line of scented candles is just 1.5 for the year, miles below their store average of 4.0. That number is a flashing red light signaling a problem. Those candles are selling way too slowly, turning into dead stock and locking up cash that could be used elsewhere.

Armed with this insight, the owner can take decisive action. They might adjust their replenishment model for that product, ordering smaller batches more often. Or maybe they’ll run a targeted marketing campaign to get those candles moving. They could even decide to cut their losses and discontinue the underperforming scents altogether. By monitoring one single KPI, they can make a data-driven decision that directly boosts profitability and frees up cash flow.

Let's be honest: manual spreadsheets and gut-feel inventory decisions just don't cut it anymore. They’re becoming relics of a bygone era. In today's e-commerce world, with thousands of SKUs and demand that can swing wildly overnight, you need a much sharper, more intelligent approach.

This is exactly where Artificial Intelligence steps in. It’s turning the replenishment of stocks from a reactive chore into a dynamic, proactive strategy that actually drives growth.

AI-powered systems forge a direct, intelligent link between your real-time sales data and your supply chain. Picture a system that constantly watches your Shopify store, registering every single sale the moment it happens. Instead of you manually crunching numbers, the AI is already analyzing sales velocity, lead times, and emerging trends to suggest the perfect purchase order—or even place it for you.

This isn’t some far-off, futuristic concept. It's an accessible and increasingly essential tool for any brand that’s serious about scaling.

The biggest win with AI? It crushes human error while managing a level of complexity that would make your head spin. Juggling hundreds or thousands of product variants—each with its own unique demand pattern—is an impossible task for any person or team. AI handles it without breaking a sweat.

These systems do more than just look at past averages; they spot the subtle patterns that are completely invisible to the human eye.

AI-driven replenishment is like having a team of a thousand expert analysts working 24/7 on your inventory. It never gets tired, never makes a calculation mistake, and is always learning how to fine-tune your stock levels for maximum profit.

There's a reason the global market for these automated systems is exploding. Valued at $9.7 billion in 2024, it's projected to hit $19.8 billion by 2033. Brands using these tools are slashing stockouts by around 35% while cutting inventory costs by up to 50%. You can dig deeper into this shift by reviewing the comprehensive research on stock replenishment systems.

Intelligent platforms don't just dump raw data on you; they deliver clear, actionable recommendations that make decisions easy. They surface the critical insights you actually need to see.

For instance, this dashboard from Tociny.ai gives you a clean sales forecast and flags potential stock issues before they become problems.

The system visualizes what’s coming and automatically generates suggestions, turning a mountain of complex analysis into a simple action plan. This lets you move faster and with a lot more confidence.

Ultimately, AI helps modern e-commerce brands make smarter, faster, and more profitable inventory decisions. It frees up your time and your capital, so you can focus on growing your business instead of getting lost in spreadsheets.

Theory is great, but cash flow and happy customers come from taking action. It’s time to build a solid system for your store's replenishment of stocks. This isn’t about complicated formulas; it’s a practical checklist you can start using today.

Think of it like building a house. You wouldn’t put up walls without a solid foundation. For your inventory, that foundation is clean, reliable data.

Your first move is to get all your historical sales data into one place. Stop toggling between spreadsheets, Shopify analytics, and random reports. The only way to get a true, unbiased view of what’s actually selling—and when, and how fast—is to centralize it all.

This single source of truth is non-negotiable for accurate forecasting. Without it, you’re just making professional guesses based on incomplete information.

Not all products are created equal, and trying to manage every single SKU with the same level of attention is a recipe for burnout and costly mistakes. This is exactly where ABC analysis shines.

It’s a simple method for categorizing your inventory based on its value to your business:

Segmenting lets you focus your energy where it matters most, making sure your bestsellers are always protected from stockouts.

With your data clean and products sorted, it's time to nail down two critical numbers: lead time and safety stock. Lead time is simply the total number of days it takes from placing an order with your supplier to the goods arriving at your warehouse. Dig into your past purchase orders to find a reliable average.

Next up is safety stock—that crucial buffer that protects you from surprise demand spikes or supplier delays. This isn't a random number you pull out of thin air; it’s a calculated cushion that prevents lost sales. For a detailed walkthrough, our guide explains how to calculate safety stock in inventory with simple, clear formulas.

Now you can match your product segments to the right replenishment models. A Reorder Point (ROP) model is perfect for your steady-selling A-Items, while a less-demanding Periodic Review system works great for your slower C-Items.

Finally, bring in a modern inventory tool. Spreadsheets get you started, but platforms like Tociny.ai automate these complex calculations, send you alerts, and deliver AI-driven forecasts that are miles ahead of manual guesswork. This is how you build a strategy that can actually scale.

An action plan isn't a one-time setup; it's a living process. Get into a rhythm of reviewing your inventory—weekly for A-Items, maybe monthly or quarterly for the others. This is your time to check your KPIs, tweak your models, and adapt as your business grows. That discipline is what turns replenishment from a headache into a powerful competitive advantage.

Diving into the world of stock replenishment always stirs up a few questions, especially for D2C brands that are scaling up. Nailing the answers can be the difference between a smooth, profitable operation and a constant battle with inventory chaos.

Let's break down some of the most common things merchants ask.

There’s no magic number here—the right frequency for reviewing your replenishment strategy comes down to how fast your products sell. This is definitely not a “set it and forget it” task.

Regular reviews are your secret weapon for adapting to market shifts and keeping your inventory perfectly balanced.

The single most dangerous mistake you can make is relying only on past sales data to predict what’s coming next. While your sales history is a fantastic starting point, treating it as gospel is a recipe for disaster.

Why? Because it completely ignores the context that drives sales up or down. This tunnel vision fails to account for things like:

A forecast built only on history is like driving a car while looking exclusively in the rearview mirror. You can see exactly where you’ve been, but you have no clue what’s just around the bend. This blind spot leads directly to frustrating stockouts or cash-draining overstock.

Absolutely. In fact, you could argue that smaller stores have the most to gain. The old idea that powerful AI inventory tools are just for massive corporations is completely outdated. Today’s platforms are more accessible, affordable, and easier to use than ever.

For a small team, the value is huge. An AI tool takes all the complex, mind-numbing calculations for demand forecasting and safety stock off your plate. This doesn't just prevent costly human errors; it frees up your most valuable resource: your time.

Instead of getting lost in spreadsheets, you can pour that energy into the things that actually grow your business—marketing, talking to customers, and developing your next great product. It levels the playing field, giving you the same powerful insights that were once reserved for the big players.

Stop guessing and start planning with precision. Tociny.ai uses AI to give your Shopify store clear sales forecasts and actionable inventory recommendations, helping you eliminate stockouts and overstock for good. Get early access to Tociny.ai and optimize your inventory today.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.