For anyone running a Shopify store, stock and replenishment can feel like a high-wire act. On one side, you have the crippling fear of that dreaded "Sold Out" tag driving you to order more. On the other, you see dusty boxes in your warehouse, and all you can think about is the cash tied up that could be fueling your growth.

This isn't just some backend chore; it's the quiet engine that powers your store's profitability. Nailing this process is what separates the D2C brands that thrive from those that are always scrambling to manage their cash flow.

Think about it: every single decision you make about your inventory sends ripples across your entire business. From customer happiness right down to your bottom line, it all connects back to how well you manage your stock.

Before we dive deeper, let's get on the same page with a few core concepts. Think of this as your quick-glance cheat sheet.

| Term | Simple Analogy | Impact on Your Shopify Store |

|---|---|---|

| Stock | The food in your pantry. | The products you have on hand, ready to ship to customers. |

| Replenishment | Your weekly grocery run. | The process of ordering new stock from your suppliers. |

| Stockout | Running out of milk for your morning coffee. | A lost sale and a potentially lost customer when an item is unavailable. |

| Overstock | Buying too much produce that goes bad. | Wasted cash, higher storage costs, and the risk of obsolete products. |

| Lead Time | The time it takes for your grocery delivery to arrive. | The time between placing an order with your supplier and receiving it. |

Understanding these terms is the first step toward building a smarter system that works for you, not against you.

Getting your replenishment strategy wrong isn't a small mistake—it's a series of costly problems waiting to happen.

It’s no surprise the global inventory optimization market is expected to reach USD 12.42 billion by 2032. Businesses are desperate for better solutions. Right now, small and mid-sized businesses are sitting on a shocking 38% excess inventory, often a knee-jerk reaction to unpredictable supply chains.

The core challenge of stock and replenishment is aligning your supply with unpredictable demand. It's about replacing guesswork with a data-driven system that anticipates customer needs before they arise, ensuring you have the right product, in the right place, at the right time.

Ultimately, a sharp replenishment strategy becomes a huge competitive advantage. While getting your inventory right is critical, remember that other tools, like a good Shopify live chat, also play a role in improving the customer experience and driving sales.

In this guide, we'll walk you through the foundational concepts and practical strategies you need to build a smarter, more resilient replenishment system for your store.

Before you can build a solid replenishment system, you need to get familiar with the blueprints—the core models that tell you when and how much to reorder. These aren't just academic theories; they're the practical playbooks that prevent stockouts and keep your warehouse from overflowing.

Think of these models like different recipes for keeping your shelves full. Each one uses a specific mix of ingredients (data points and metrics) to achieve the same delicious outcome: happy customers and healthy cash flow. Let's dig into the most common approaches we see in e-commerce today.

The Reorder Point (ROP) model is probably the most intuitive and widely-used method out there, and for good reason. It’s a perpetual system, which just means it keeps a constant eye on your stock levels. When a product dips below a specific threshold, it automatically triggers a new order.

It’s just like the gas light in your car. You don’t wait until the tank is completely empty to find a gas station. That light flicks on when you still have a buffer, giving you plenty of time to refuel. Your ROP is the gas light for your inventory.

The ROP formula is designed to signal the perfect moment to place a purchase order. It ensures new stock arrives just as you start dipping into your safety buffer, not after it's gone.

This proactive approach works beautifully for products that have relatively stable, predictable demand. It takes the guesswork and last-minute panic out of your ordering process.

Of course, no model is any good without the right data. These are the crucial inputs that make any replenishment strategy tick.

Lead Time: This is the entire time it takes from the moment you hit "send" on a purchase order to when that product is on your shelf, ready to sell. It covers everything—supplier processing, production, shipping, and receiving. Getting this number wrong is one of the fastest ways to an unexpected stockout.

Safety Stock: Think of this as your "just in case" inventory. It's the extra buffer you keep on hand to protect against things you can't control, like a sudden surge in demand or a delay from your supplier. Without it, even a small hiccup can lead to a dreaded "out of stock" notice.

Inventory Turnover: This metric simply tells you how many times you sell through your entire inventory in a given period. A high turnover rate is fantastic—it means products are flying off the shelves and your cash isn't locked up in slow-moving stock. A low rate, on the other hand, can be a red flag for overstocking.

While ROP is a crowd-pleaser, it’s not the only game in town. Depending on your products and suppliers, one of these other systems might be a better fit.

Periodic Review Model Instead of ordering when stock hits a certain level, this model works on a fixed schedule. You might place orders every Tuesday, or on the first of every month. The amount you order changes each time, with the goal of bringing your stock back up to a pre-set maximum. This is great for simplifying orders with suppliers who have fixed delivery dates.

Min/Max Model This is a really straightforward take on the ROP model. You set two levels: a minimum (Min) and a maximum (Max). As soon as your inventory drops to the Min level, an order is placed to bring it all the way back up to the Max. It's easy to set up and works well for brands that want to keep their inventory levels within a tight, predictable range.

Each model has its place. And for those who really want to dial in their reorder quantities, digging into concepts like the Economic Order Quantity (EOQ) can unlock even more efficiency. To learn more, check out our guide on what is Economic Order Quantity. The real secret is matching the right model to each product's sales velocity and your supplier's reliability.

Even the most brilliant product or marketing campaign can be completely torpedoed by sloppy stock and replenishment practices. I’ve seen it time and time again: D2C brands unknowingly sabotage their own success by falling into common traps that drain cash, frustrate customers, and stunt growth.

These aren't dramatic, one-time disasters. They are subtle, corrosive habits that silently eat away at your profitability. Recognizing these patterns in your own operations is the first—and most critical—step toward building a more resilient inventory system.

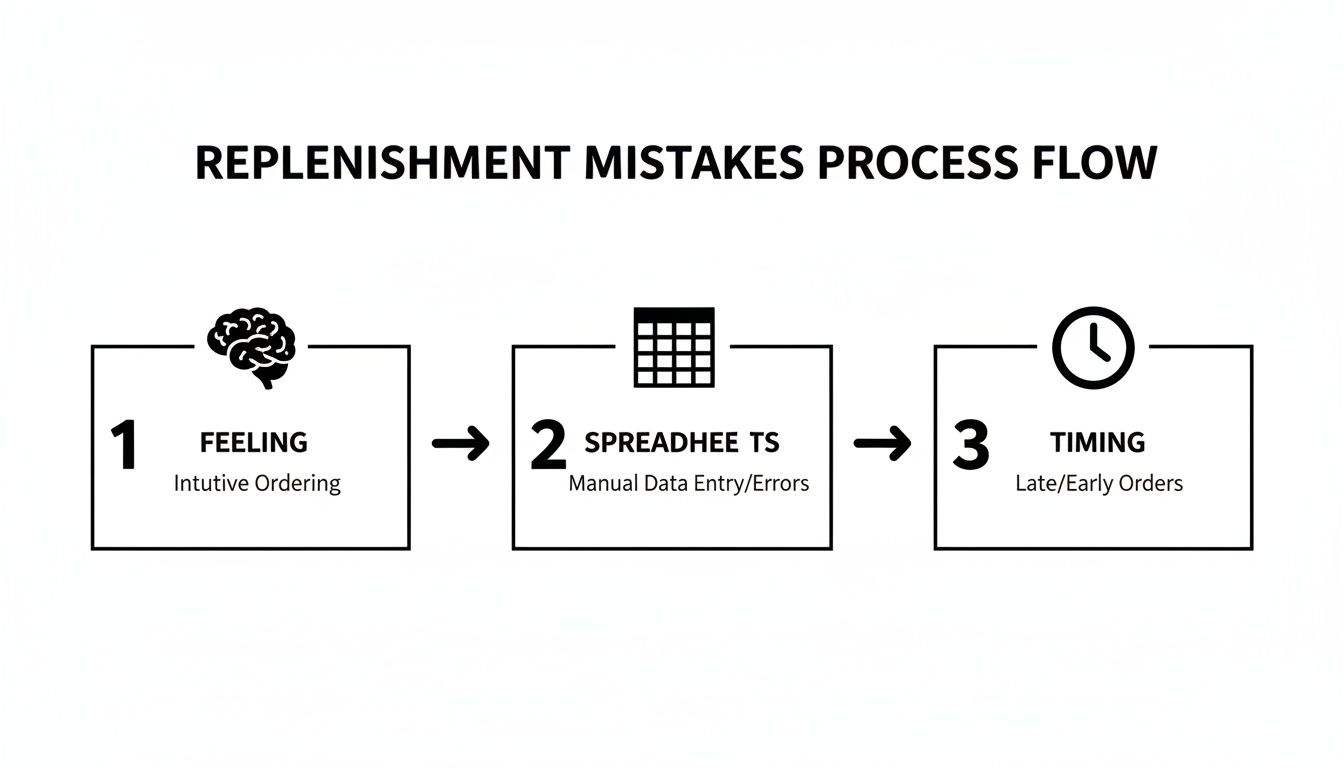

One of the biggest mistakes I see is managing inventory by intuition. A founder might think, "Our blue hoodie flew off the shelves last month, let's double the order!" This gut-feel approach is a gamble, plain and simple. It completely ignores seasonality, emerging trends, or a competitor's flash sale that might have temporarily juiced your numbers.

Imagine a skincare brand launching a new holiday gift set. Feeling optimistic after a strong Q3, the founder places a massive order, expecting a sell-out season. What they didn't account for was a key ingredient's sudden trendiness fading, or a competitor launching a similar, better-marketed set.

Come January, they're stuck with thousands of unsold holiday-themed boxes. That’s cash that’s now tied up, cash that could have been used for new product development. This is the classic outcome of replacing data-driven forecasting with hopeful guesswork.

For new brands, spreadsheets feel like a sensible, low-cost way to start. But as your SKU count grows and you add more sales channels, those static documents quickly become a liability. They are magnets for human error, create version control nightmares, and have zero ability to analyze complex data patterns on the fly.

A single copy-paste error or an outdated formula can lead you to order 5,000 units instead of 500, turning a profitable product into a financial deadweight. These manual systems just can't keep up with the pace of modern e-commerce, creating blind spots that hide expensive problems until it's far too late.

Overstocking isn't just a minor headache; it's a systemic cash drain. Research shows that retail sectors in North America hold 24% excess stock as a percentage of their total inventory. This highlights a persistent struggle for small and mid-sized businesses to move their inventory efficiently. You can dig into more insights on this challenge in the full research on supply chain planning.

Another all-too-common misstep is treating supplier lead times as a fixed, reliable number. You might assume your supplier always delivers in 21 days because that's what the contract says. But what about customs delays, port congestion, or production hiccups on their end? Real-world logistics are messy.

Failing to track the actual delivery time for every single purchase order is a recipe for disaster. If your reorder point is calculated using a 21-day lead time, but your deliveries have actually been averaging 35 days, you've just created a 14-day window where you are guaranteed to stock out.

This doesn't just mean lost sales. It damages your brand's reputation for reliability. Effective stock and replenishment has to be built on real-world variability, not just on-paper estimates.

If you’re ready to move beyond reactive, “gut-feel” ordering, you need a plan. A formal, documented replenishment policy is what turns inventory management from a frantic guessing game into a repeatable, strategic system. This isn't just about writing things down; it's about building a resilient, data-driven engine that grows with your Shopify store and empowers your team to make consistently smart decisions.

Think of it as the official playbook for your inventory. Without one, every reorder is an improvised play based on hunches and whatever’s on fire that day. With a policy, everyone on your team knows exactly when to act, how much to order, and why. That consistency is the bedrock of efficient stock and replenishment, stopping the costly mistakes that creep in when every decision is made in a vacuum.

This process flow shows the all-too-common pitfalls a smart policy helps you sidestep, moving you from feeling-based decisions and spreadsheet errors to precise, well-timed actions.

As you can see, the path from instinct to manual error to poor timing is a slippery slope that tanks your inventory health. Let's build the system that prevents this from happening.

Not all products are created equal, so they shouldn't be managed that way. ABC analysis is a dead-simple yet powerful method for segmenting your inventory based on its value to your business. It’s built on the Pareto Principle, which suggests that roughly 80% of your revenue flows from just 20% of your products.

By classifying your SKUs, you can focus your energy and capital where they’ll make the biggest splash.

This segmentation is liberating. It allows you to design different strategies for each category, optimizing your efforts instead of treating every single product with the same intense level of scrutiny.

Before you set your replenishment rules, you need to decide how to apply them. Combining ABC analysis with your desired service levels gives you a clear roadmap.

| SKU Category (ABC) | Characteristics | Recommended Replenishment Strategy | Key Metric to Watch |

|---|---|---|---|

| A Items | Top sellers, high revenue impact. A stockout here is painful. | Use a Periodic Review or continuous model. Set a high service level (98-99%) and maintain robust safety stock. | Service Level, Stockout Rate |

| B Items | Consistent performers, moderate revenue impact. | A Reorder Point (ROP) system works well. Aim for a solid service level (90-95%) with moderate safety stock. | Inventory Turnover, Fill Rate |

| C Items | Slow movers, low revenue impact, often unpredictable. | Use a simple Min/Max system or periodic bulk orders. A lower service level (80-85%) is acceptable. | Days of Supply, Carrying Costs |

This table provides a blueprint for tailoring your approach, ensuring you're not wasting resources on low-impact items while leaving your bestsellers vulnerable.

Once you know which products matter most, it's time to crunch the two most critical numbers in your policy: the reorder point (ROP) and safety stock. These metrics are the triggers and buffers that put your replenishment decisions on autopilot.

The ROP tells you when to place an order. The basic formula is refreshingly straightforward:

Reorder Point = (Average Daily Sales × Lead Time in Days) + Safety Stock

This ensures you place a new order while you still have enough stock to cover customer demand during the supplier's lead time—plus a little extra just in case.

That "little extra" is your safety stock. Think of it as your insurance policy against unexpected supply chain delays or sudden spikes in demand. Without it, your entire system is brittle, ready to snap and cause a stockout the moment something deviates from the forecast. For a deeper dive into getting this crucial buffer right, you can learn more about how to calculate safety stock using more advanced formulas.

Let’s walk through a quick example. Imagine you sell a popular face serum (a classic 'A' item).

Your ROP calculation would be: (10 units/day × 14 days) + 50 units = 190 units

This means the moment your on-hand inventory for that serum dips to 190 units, your policy kicks in and triggers a new purchase order. This simple, data-driven rule removes all the guesswork and ensures you never get caught flat-footed. Setting these calculations for your key products is the true engine of a smart, proactive replenishment policy.

Let's be honest, most traditional replenishment methods have a major flaw: they're always looking backward. You're essentially driving your business by staring into the rearview mirror, reacting to what’s already happened. An AI-powered approach completely flips the script. It’s like swapping that rearview mirror for a live GPS that sees traffic jams, weather delays, and road closures miles down the road.

AI systems don’t just spit out reorder points based on last year’s sales averages. They dive deep, analyzing thousands of data points in real time—everything from your sales history and current market buzz to a competitor’s weekend promo and even broader economic shifts. For a Shopify store owner, this is a massive upgrade, moving you from a basic calculator to a predictive supercomputer.

The real magic here isn’t just seeing what you sold. It’s finally understanding the why behind those sales, which is the key to making much smarter bets on what to stock next.

One of the biggest wins AI brings to stock and replenishment is freeing you from the tyranny of the spreadsheet. Instead of losing hours manually tweaking safety stock levels or calculating reorder points for hundreds of SKUs, an AI platform handles it all—continuously and automatically.

This kind of automated brainpower is a lifesaver in today’s choppy market. We’re all still dealing with supply chain headaches, where lead times can be unpredictable and much longer than they were a few years ago. It’s no surprise that companies using AI for planning report 15% fewer stockouts; the tech is just better at adapting on the fly. And as keeping costs in check becomes a top priority, having a tool that prevents you from tying up cash in expensive overstock is a no-brainer.

At its heart, AI is brilliant at spotting patterns a human could never hope to see. This superpower is an absolute game-changer for demand forecasting, which is the bedrock of any solid replenishment plan.

An AI-driven forecast doesn't just see that you sold more sunscreen in July. It connects the dots between a three-day heatwave forecast, a recent influencer shout-out, and a competitor's stockout to predict a very specific spike in demand for your SPF 50 lotion next Tuesday.

This level of granularity transforms your inventory management from a reactive chore into a proactive, strategic weapon. It lets you:

This predictive muscle is especially crucial for D2C brands that need to be nimble to stay ahead. To see how this works under the hood, check out our guide on AI demand forecasting.

For anyone running a Shopify store, bringing AI into your replenishment workflow isn't about chasing the latest tech fad. It's about real, tangible results that hit your bottom line.

Platforms like Tociny.ai plug directly into your store's data, chewing through your sales history and product performance to deliver clear, actionable advice. The system can flag which products are turning into slow-movers, predict your next bestsellers, and suggest the exact reorder quantities to keep things humming.

This completely removes the guesswork that so often leads to expensive mistakes. Instead of agonizing over whether to reorder 100 units or 150, the AI gives you a data-backed number designed to maximize your sales while keeping excess stock to a minimum. The end result is a more resilient business with healthier cash flow, happier customers, and more of your time freed up to actually grow your brand.

Even with a killer replenishment policy on paper, the real world always throws curveballs. Managing your inventory isn't a "set it and forget it" task—it's a constant cycle of monitoring, tweaking, and learning from what your sales data is telling you.

This is where we get practical. Let's tackle the most common questions we hear from Shopify store owners, turning theory into actionable answers you can use to sharpen your strategy and handle the day-to-day challenges like a pro.

The honest answer? It depends entirely on the product. Applying the same review schedule to every item in your catalog is a fast track to wasting time and taking on unnecessary risk. A much smarter approach is to let your ABC analysis guide your focus.

Your A-listers—those 'A' items that drive the bulk of your revenue—need constant attention. You should be checking in on their stock levels and sales velocity at least weekly. These are the heart of your business, and a stockout, even for a day, can be incredibly painful. A weekly check-in lets you spot a sudden sales spike or a surprising slowdown before it snowballs into a real problem.

For your steady-but-less-critical 'B' items, a bi-weekly or monthly review usually does the trick. And for your slow-and-steady 'C' items, a quarterly checkup is a perfectly reasonable place to start. This tiered system ensures your most valuable time is spent on your most valuable products.

The best replenishment systems aren't static; they're dynamic. Your review schedule should adapt to sales cycles, supplier lead times, and market surprises. This is where an AI platform shines, automating the constant monitoring and flagging what needs your attention in real-time, so you aren't stuck on a rigid schedule.

So many people use "safety stock" and "reorder point" interchangeably, but they're two very different—and equally vital—levers in your replenishment machine. Getting this right is fundamental to avoiding stockouts.

Let's break it down simply:

Your reorder point is calculated to cover all the sales you expect to make while waiting for your next shipment to arrive. The formula is essentially (Average Daily Sales x Lead Time in Days) + Safety Stock. Notice that safety stock is baked right into the reorder point calculation.

Without that buffer, your ROP is a tightrope walk with no safety net. The moment a supplier is late or an influencer gives you a surprise shoutout, you're stocked out. The ROP is your action trigger; safety stock is the cushion that makes the entire system work without giving you a heart attack.

For a brand-new store with just a handful of SKUs, Shopify's basic inventory tracking is a fine place to start. It lets you see your current stock levels for each variant, and when your operation is simple, that's often enough to get by.

But you'll hit a ceiling, and you'll hit it fast. As your business scales, you'll discover that Shopify’s native tools are missing the advanced features you need to manage inventory intelligently. We're talking about crucial functions like:

Once you’re managing more than a few products, trying to do all this in a spreadsheet is not only a massive time-suck, but it's also dangerously prone to human error. To truly optimize your cash flow and protect your revenue at scale, you need a dedicated inventory planning tool that gives you predictive insights.

Ah, the dreaded supplier delay. It's one of the biggest headaches in e-commerce. A quoted lead time of 21 days can easily bloat to 30 or 40 because of customs delays, port congestion, or production hiccups. Building a resilient stock and replenishment plan means planning for this volatility.

The first step is non-negotiable: track the actual delivery time for every single purchase order. Stop relying on the "official" lead time your supplier quotes you. You need to know your real-world average and, just as importantly, the longest delay you've ever had to endure. For instance, your data might reveal that a supplier's lead time is "usually 14 days, but has been as long as 21."

That data is your best defense. You can then use this historical performance to calculate your safety stock, specifically building in a buffer to cover that maximum likely delay. It's how you protect yourself from the unpredictability you know is coming.

This is an area where AI tools offer a massive advantage. An AI platform like Tociny.ai can analyze all your historical supplier data, spot patterns in delays you might miss, and automatically adjust your safety stock and reorder points to account for that variance. You shift from a reactive mode—panicking when a shipment is late—to a proactive one, where your inventory plan already anticipates the disruption. That means a much more robust and stress-free operation.

Ready to stop guessing and start growing? Tociny.ai replaces spreadsheet chaos with clear, AI-powered inventory recommendations, helping you reduce stockouts and unlock cash flow. Get early access and see what your data is telling you.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.