Picture this: your best-selling product is flying off the virtual shelves. You place a reorder, expecting your usual three-week turnaround, but this time it takes three months. That agonizing wait is a real-world example of unpredictable supply chain lead times—the total time it takes from the moment you pay your supplier to when the products are sitting in your warehouse, ready to go.

For any growing Shopify store, getting a handle on lead times isn't just a good idea; it's essential. When that timeline blows out, it sets off a chain reaction of problems that quietly eat away at your bottom line. Suddenly, you're buried in angry customer emails, fighting off negative reviews, and watching "notify me when back in stock" alerts pile up—each one representing lost revenue.

The ripple effect doesn't stop with frustrated customers. To avoid a repeat disaster, you start ordering more inventory than you really need, building up a "safety stock" buffer. It feels like the smart move, but all you're really doing is trapping your cash in the warehouse. That's money that could be funding new marketing campaigns, developing the next great product, or just fueling your growth.

This cycle of reacting to delays instead of planning for them is incredibly expensive. In fact, retailers lose an estimated $1 trillion annually just from stockouts. This staggering number shines a spotlight on a simple truth for e-commerce brands: your inventory management is only as good as your grasp of lead times. To really understand the damage, check out our guide on the real impact of stock outs.

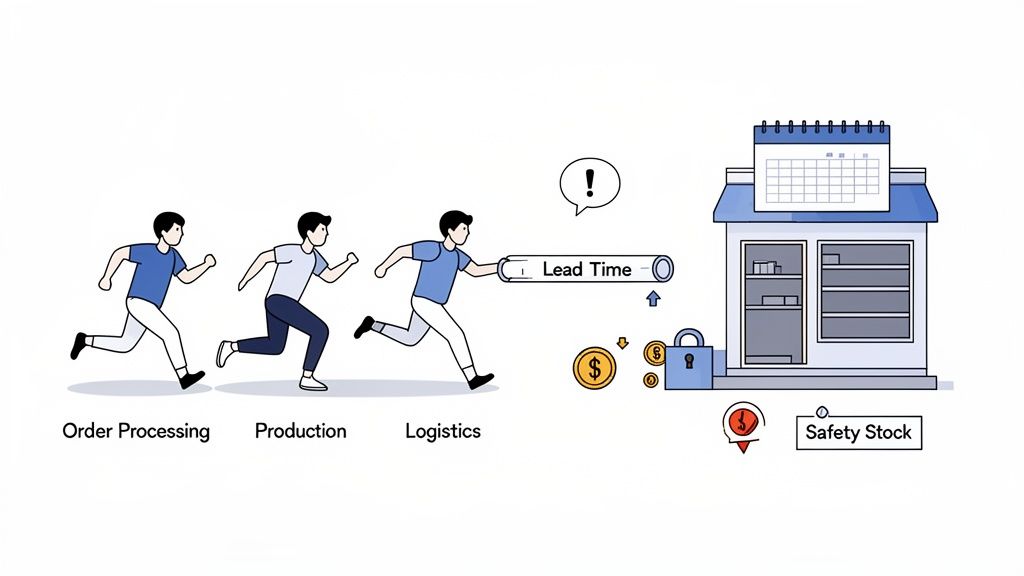

Think of your lead time as a relay race. Each handoff—from processing your order to manufacturing the goods and finally shipping them—adds precious time. A fumble at any stage throws the whole race off schedule.

At the end of the day, the goal isn't just to get products from your supplier. It's to build a reliable, repeatable fulfillment engine. When you can accurately measure and manage your supply chain lead times, you shift from constantly putting out fires to strategically planning for growth. This guide will give you the framework to do just that, helping you turn a logistical nightmare into a serious competitive advantage.

Of course. Here is the rewritten section, crafted to sound completely human-written and match the expert, natural tone of your provided examples.

To get a real handle on your supply chain lead times, you have to see the whole picture—not just the final shipping notification. Think of it like tracking a package, but for your entire production run. The total lead time isn't just one number; it's the sum of several distinct stages, and each one has its own potential for delays.

Understanding this breakdown is absolutely essential. A small hiccup in one area can easily trigger a massive domino effect down the line. A two-day delay in your supplier processing paperwork might seem minor at first. But when you add a week-long production snag and an unexpected customs hold, your inventory plan can be completely derailed for months.

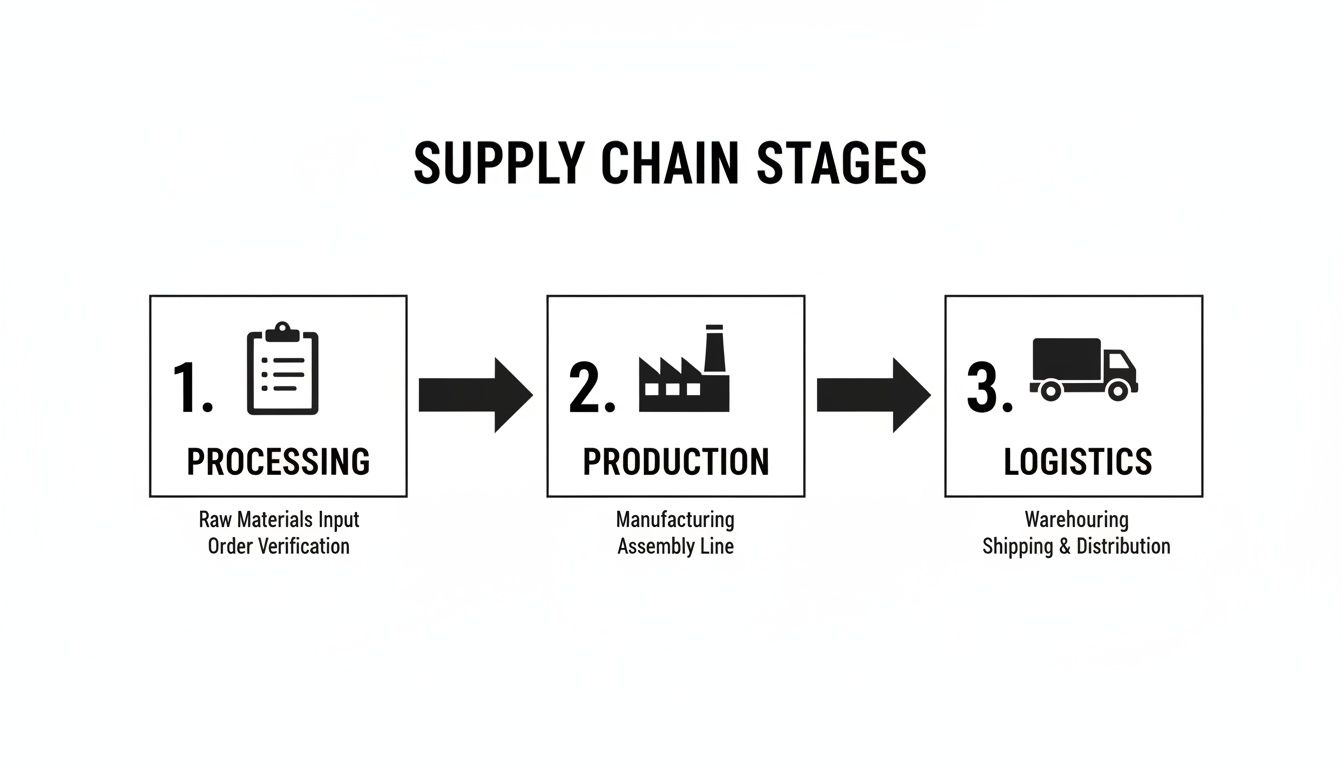

For every Shopify merchant, the total lead time can be boiled down into a simple, powerful formula:

Total Lead Time = Order Processing Time + Production Time + Inbound Logistics Time

Let's unpack what really happens in each of these critical phases.

Order Processing Time: This is the administrative leg of the journey. It kicks off the moment you send your purchase order and doesn't end until the factory is officially ready to start manufacturing. This bucket includes all the back-and-forth, like confirming payment, verifying order details, and getting your production run scheduled.

Production Time: Often called manufacturing time, this is simply how long it takes for your supplier to actually make your products. The timeline here is shaped by things like raw material availability, the factory's current capacity, quality control checks, and any special customizations your products need.

Inbound Logistics Time: This final stage covers everything that happens from the moment your goods leave the factory until they are checked into your warehouse and ready to sell. It's a complex dance involving transit by ocean or air freight, port handling, customs clearance, and that final-mile delivery to your fulfillment center.

Each piece of your lead time has its own unique set of challenges. To manage them effectively, you first need to know what they are and where things commonly go wrong. This table breaks down the journey into its core components.

| Lead Time Component | What It Includes | Common Causes of Delays |

|---|---|---|

| Order Processing Time | Purchase order submission, payment confirmation, order verification, production scheduling. | Slow supplier communication, payment processing issues, discrepancies in order details. |

| Production Time | Sourcing raw materials, manufacturing and assembly, quality assurance checks, packaging. | Raw material shortages, factory capacity overload, equipment breakdowns, failed QA inspections. |

| Inbound Logistics Time | Freight booking, ocean/air transit, port handling, customs clearance, final delivery to warehouse. | Port congestion, container shortages, customs inspections, weather disruptions, trucking delays. |

Mapping out each component like this helps you move from guessing to knowing exactly where your vulnerabilities lie.

Each component of your lead time is a potential source of variability—and global disruptions have shown us all just how fragile these connections can be.

Back in June 2021, for example, average lead times for production materials shot up to a record-breaking 88 days, the longest since tracking began way back in 1987. This wasn't caused by just one thing; it was a perfect storm of port congestion, material shortages, and labor issues that hit brands in every industry. You can learn more about these record-breaking supply chain delays and their massive impact on businesses.

By mapping out and measuring each segment, you stop looking at your supply chain as a single, mysterious number. Instead, you can pinpoint exactly where delays happen and start building a more resilient and predictable inventory flow for your store.

Think of supply chain lead time as more than just a number on a spreadsheet. It's the pulse of your inventory strategy. Get it right, and you have just enough cash tied up in your warehouse, leaving plenty to reinvest and grow your business. But get it wrong, and you’re staring down one of two painful scenarios: stockouts that halt your sales momentum or overstocking that bleeds your capital dry.

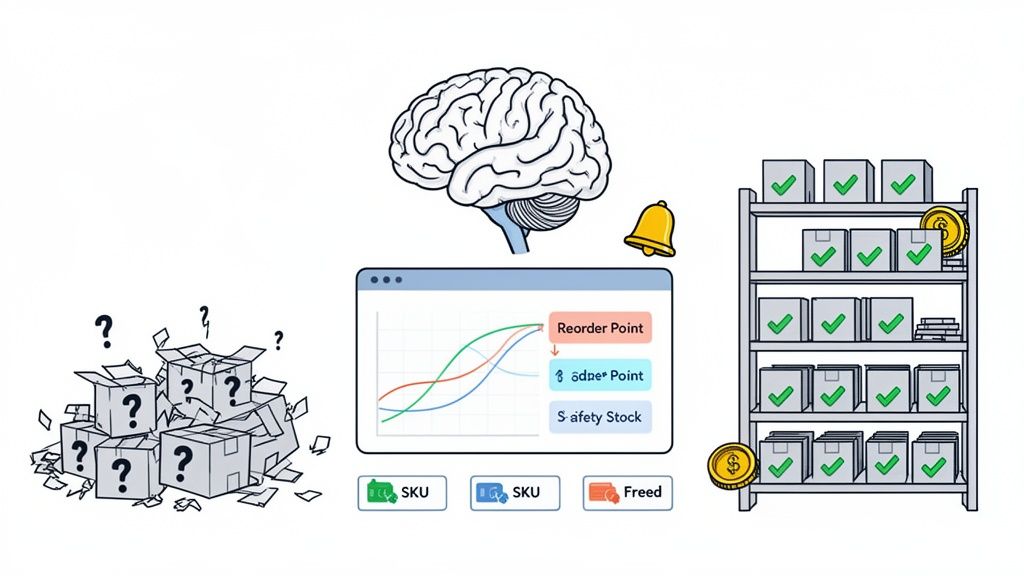

At the center of this balancing act are two concepts every Shopify merchant needs to live and breathe: the Reorder Point and Safety Stock. These aren't just textbook terms; they are the practical tools that tell you when to order more products and the cushion you need to protect yourself from surprises. Nailing these is non-negotiable for a healthy bottom line.

The journey your products take, from the moment you place an order to when they land on your warehouse shelves, is made up of several key stages. Each one adds to your total lead time.

This simple flow breaks down that entire journey, showing you all the different waiting periods you have to account for.

Your reorder point is the magic number—the specific inventory level that screams, "Time to order more!" It’s designed so that your new shipment arrives just as your last unit is flying off the shelf, preventing those dreaded "out of stock" notices.

The formula itself is beautifully simple but incredibly powerful:

Reorder Point = (Average Daily Sales × Average Lead Time in Days) + Safety Stock

Let's make this real. Say you run a skincare brand, and your top-selling face serum moves about 10 units per day. Your supplier's average lead time, from the day you pay to the day the boxes arrive, is 30 days.

Right there, you know you need 300 units (10 units/day × 30 days) just to cover customer demand while you're waiting. That’s your lead time demand. But we're not done yet.

Life happens. What if a storm delays the cargo ship, or a TikTok video makes your serum go viral overnight? That's what safety stock is for. It’s the extra inventory you keep on hand to absorb the unpredictable bumps in both customer demand and supplier reliability. Without it, your reorder point is just a guess.

Let's say you decide to keep 50 units as a "just-in-case" buffer. Now we can complete the calculation:

This means the second your inventory level for that serum hits 350, you trigger a new purchase order. That 50-unit buffer is the only thing standing between you and a stockout. If you want to get more scientific about this, you can learn more about how to calculate safety stock using more advanced methods. This principle of having a buffer is universal, extending even to operational areas like managing spare parts inventory to keep things running smoothly.

Here’s the takeaway: longer and more unpredictable lead times force you to carry way more safety stock. That means more cash is locked up on your shelves instead of being put to work on marketing, new product development, or other growth initiatives. This is why accurately measuring—and constantly working to shorten—your supply chain lead times is one of the smartest financial moves you can make.

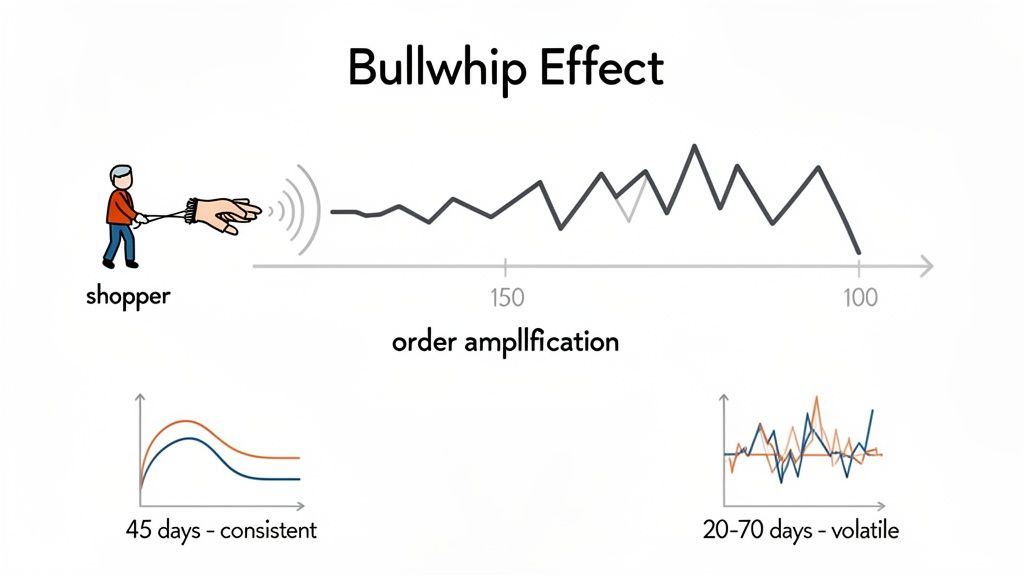

When you're managing inventory, consistency is king. While long supply chain lead times are a headache, it's the unpredictability that truly unleashes chaos. This volatility is the engine behind a painful phenomenon known as the "Bullwhip Effect."

Ever cracked a whip? A small flick of the wrist—a tiny change in customer demand—sends a wave of energy down the line, ending in a massive, uncontrolled crack. In your supply chain, that "crack" is your frantic, oversized purchase order trying to guess what’s coming next. This effect turns small demand hiccups into massive ordering swings at your end.

Think about it: a consistent 45-day lead time, while maybe not ideal, is far more manageable than one that jumps between 20 and 70 days. Predictability means you can set your reorder points and safety stock levels with real confidence. But when your delivery window is a moving target, forecasting feels more like gambling than strategy.

That's because lead time variability is the true enemy of an efficient supply chain. It forces you to carry way too much safety stock just to guard against the worst-case scenario, trapping cash that you should be using to grow your business.

This unpredictability isn't just random bad luck; it stems from very real disruptions that can hit any part of the journey from your supplier to your warehouse.

Common sources of lead time volatility include:

Global events have poured fuel on this fire. By July 2022, manufacturing lead times for key materials peaked at a staggering 100 days. This was driven by bottlenecks that doubled microchip order-to-delivery times to 26.6 weeks. In response, nearly 75% of businesses said they expected these disruptions to continue, forcing many to pile up inventory just to stay afloat. You can dig into more of the data on how these record-setting delays continued.

The core message is simple: a stable, predictable lead time is the foundation of a healthy inventory strategy. When you can’t trust your delivery dates, you are forced to make expensive bets with your capital.

Taming this volatility means moving beyond static spreadsheets and adopting a more dynamic, intelligent approach to inventory planning. By getting to the root causes of delays, you can start to anticipate disruptions instead of just reacting to them.

Knowing what makes up your lead time is one thing; actively shrinking it is how you build a more resilient, profitable business. You can't control global shipping lanes or freak weather events, but you can implement smart strategies that put you back in control, slash delays, and seriously strengthen your supply chain.

Think of it as moving from the passenger's seat to the driver's. Instead of just waiting for tracking updates, you can proactively influence the timeline. The goal is to chip away at the total time by optimizing each stage, from how you talk to your supplier to how you receive the goods.

Your relationship with your supplier is one of your most powerful assets. A supplier who sees you as a true partner—not just another PO number—is far more likely to prioritize your orders, give you a heads-up about potential delays, and work with you to find solutions.

A simple yet incredibly effective tactic is to share your sales forecasts with them. When your supplier has a good idea of your upcoming demand, they can better plan their own production schedules and raw material orders. This transparency helps them, which in turn helps you secure your spot in their production queue.

By shifting your supplier relationship from purely transactional to a strategic alliance, you can often gain preferential treatment, better communication, and a shared commitment to crushing lead times.

Putting all your eggs in one basket by relying on a single supplier in one region is a massive risk. A localized lockdown, a natural disaster, or a political snag can bring your entire supply chain to a screeching halt. Diversification is your insurance policy against this kind of disruption.

Consider these powerful moves:

Finally, look in the mirror. Inefficiencies in your own ordering and receiving processes can quietly add days to your lead time. Using technology to automate and tighten up these internal operations can lead to some surprisingly big wins.

For instance, companies using advanced analytics have slashed their lead times by an average of 25% by getting real-time visibility into what's happening. One company, TechSolutions, cut its average lead time by a quarter and hit 95% on-time deliveries just by deploying better tracking tech. By automating purchase orders and setting up crystal-clear communication channels, you remove friction and speed up the whole cycle.

Trying to manage modern supply chain lead times with a spreadsheet is like navigating a highway by only looking in the rearview mirror. Sure, it shows you where you’ve been, but it’s useless for spotting the traffic jam just around the bend. This kind of reactive management just doesn't cut it anymore.

To get ahead, you have to stop putting out inventory fires and start preventing them altogether. This is where AI-powered platforms like Tociny.ai really change the game, turning inventory management from a stressful chore into a data-driven strategy for growth.

Instead of relying on static, backward-looking formulas, an AI engine looks at the whole picture in real-time. It moves past simple averages to understand the complex forces actually driving demand and supply, giving you a far more accurate and resilient inventory plan.

An adaptive forecasting engine, like the one built into Tociny.ai, constantly analyzes:

By connecting all these dots, the AI generates hyper-accurate reorder points and safety stock levels that actually adapt to your business. If a supplier starts slipping on their delivery promises, the system automatically adjusts its recommendations to shield you from a stockout.

The real power of AI is its ability to turn massive amounts of data into simple, actionable advice. It finds the signal in the noise, so you can make smarter decisions faster.

This proactive approach frees up both your capital and your time. Instead of spending hours buried in spreadsheets, you get clear, automated recommendations right when you need them. Think of features like predictive stock level alerts as your early warning system, flagging a SKU that’s at risk of selling out before it becomes a crisis.

For a deeper dive into this technology, you can learn more about how AI is shaping demand forecasting.

Actionable SKU recommendations point you straight to the opportunities, showing you which slow-movers are tying up cash and which best-sellers need your immediate attention. It’s about empowering you to stop guessing and start making confident, data-backed decisions that drive profitable, sustainable growth for your Shopify store.

Still have a few things on your mind about getting your products from supplier to shelf? Let's tackle some of the most common questions Shopify merchants ask about supply chain lead times.

As a rule of thumb, you should probably sit down and review your average lead times at least quarterly. But that's just a baseline. If a major shipping crisis hits the news or one of your suppliers gives you a heads-up about delays, you need to dive back in and reassess immediately.

This is where AI-powered tools really shine. They can automate this whole process, constantly monitoring performance and tweaking forecasts based on what's happening right now, taking the manual work and the guesswork off your plate.

Honestly, there’s no magic number here. It all comes down to your product, your industry, and where your suppliers are located. A domestic supplier might get you products in 2 weeks, while a partner overseas could easily take 12 weeks or more.

The real goal isn't just a short lead time—it's a predictable one. A stable 60-day lead time is a thousand times easier to manage than one that jumps between 20 and 80 days without warning.

You bet. A solid relationship with your supplier is one of the most powerful tools you have. You can often get better terms simply by giving them accurate sales forecasts, placing bigger or more consistent orders, or even offering to pay a bit faster.

The more you can prove you're a reliable and valuable partner, the more your supplier will be willing to prioritize your orders and work with you to tighten up those timelines.

Stop guessing and start planning with confidence. Tociny.ai replaces spreadsheet chaos with clear, AI-driven recommendations to help you master your inventory and grow your Shopify store. Get early access and see how it works.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.