Inventory shrinkage is one of those sneaky problems that can quietly eat away at your profits. It's the difference between the stock you think you have in your system and what's actually sitting on your warehouse shelves.

For any e-commerce brand, especially those on Shopify, this gap isn't just a minor bookkeeping headache—it's a direct hit to your bottom line.

Think of it like a slow leak in a tire. It might not seem like a big deal at first, but if you ignore it, you’ll eventually find yourself stranded. That’s exactly what inventory shrinkage does to a business. It's a constant, silent drain on your resources.

This isn’t just about someone swiping a product off a shelf. While theft is definitely part of the equation, the reality of shrinkage is much broader and often rooted in simple, everyday operational hiccups.

Let's break down the four most common culprits behind inventory shrinkage. Understanding where the leaks are coming from is the first step to plugging them for good.

The table below breaks down the main categories of shrinkage, helping you quickly diagnose potential weak points in your own operations.

| Cause of Shrinkage | Description | Example for a D2C Store |

|---|---|---|

| Administrative Errors | Everyday human mistakes. Think data entry typos, miscounted shipments, pricing errors, or misplaced items that create "phantom" inventory in your system. | Your supplier sends 100 units of a new face cream, but an employee accidentally enters 110 into the system. You now have 10 ghost units you might sell but can't fulfill. |

| Damage | Products that get damaged during shipping, receiving, or just moving around the warehouse. Once a product is broken or unsellable, it's effectively gone. | A box of fragile glass candle jars is dropped during unloading. Half of them crack, making them unsellable and instantly turning them into shrunken inventory. |

| Vendor Fraud | This happens when a supplier doesn't send what they billed you for. They might short-ship an order but invoice for the full amount. It’s surprisingly easy to miss without a solid receiving process. | You order 500 t-shirts from a manufacturer, but they only ship 485. If your team doesn't count the delivery and just pays the invoice for 500, you’ve just paid for 15 shirts that never existed. |

| Theft | This is the one everyone thinks of first. It covers everything from organized retail crime (external) to employees pocketing items (internal). | An employee helps themselves to a few high-end electronic gadgets over several months, or a porch pirate steals a package that was returned by a customer. |

As you can see, shrinkage is a complex issue with roots in nearly every part of the fulfillment process.

If you're running a store in a competitive niche like fashion, wellness, or electronics, your profit margins are probably already pretty tight. Even a small amount of shrinkage can be the difference between a profitable month and a loss.

Imagine that D2C skincare brand again. They receive a shipment of their best-selling serum, but an employee miscounts the delivery, recording 500 units instead of the actual 480. That single mistake creates a ripple effect. The system shows 20 extra units are available, leading to overselling, disappointing customers with stockouts, and making bad reordering decisions based on faulty data.

Inventory shrinkage isn’t just a line item on a spreadsheet; it’s a direct reflection of your operational health. Ignoring it is like trying to grow a business while leaving the back door wide open for profits to walk right out.

The financial toll is massive and getting worse. In the U.S. alone, shrinkage rates climbed to 1.6% of sales, which translated to a staggering $112.1 billion in losses in 2023. Globally, the problem is expected to hit $132 billion in 2024. You can learn more from these retail shrinkage trends and statistics to see just how deeply this silent problem cuts across businesses of all sizes.

By getting a handle on what causes it, you can finally start to plug the leaks and protect your hard-earned revenue.

When a product vanishes from your inventory, the direct cost of that lost item is just the tip of the iceberg. The real damage from inventory shrinkage ripples across your entire business, painting a distorted picture of your operational health that leads to one bad decision after another.

Think of these inaccuracies as a fog rolling into your warehouse. They obscure what’s truly happening with your sales and demand, leading to two equally damaging outcomes.

First, you get frustrating stockouts on your most popular items. When your system thinks you have more stock than you actually do, you’ll inevitably sell products you can’t ship. This costs you immediate sales, sure, but the real sting comes from the hit to customer loyalty.

On the flip side, this same bad data can cause crippling overstocks. This happens when you mistake shrinkage for legitimate sales and reorder products that aren't actually flying off the shelves. All this does is tie up valuable cash in dead stock and rack up unnecessary storage fees. For a deeper look into these expenses, you can explore our guide on what is inventory carrying cost.

Imagine a Shopify fashion brand selling a trendy graphic t-shirt. A few units get stolen from the warehouse each week, but the inventory system is blissfully unaware. It just registers the items as "gone."

The operations manager, looking at the data, sees the t-shirt's stock level dropping fast. They mistake this shrinkage for a surge in customer demand and, wanting to capitalize on the "trend," place a huge reorder.

But when the new shipment arrives, the sales just aren't there. The velocity doesn't match the ghost demand created by the theft. Now, the brand is stuck with hundreds of extra shirts destined for the clearance rack, completely eating their profit margins—all because bad data told them a story that wasn't true.

This infographic really drives home the scale of the problem.

As you can see, even a small percentage loss quickly balloons into billions of dollars in damage, driven by a handful of core causes.

The consequences go far beyond a single bad reorder. Flawed inventory data poisons your entire operational workflow, setting off a chain reaction of problems that drain both time and money.

This broader issue, known as inventory distortion, results in a staggering $1.73 trillion in annual global retail losses from both stockouts and overstocks. That figure is equivalent to 6.5% of worldwide sales—a number comparable to the entire GDP of South Korea. You can read more about these startling retail inventory crisis findings from IHL Group's 2025 analysis.

This massive disconnect leads to several tangible business pains:

Ultimately, inaccurate data forces you to run your business in reactive mode, constantly putting out fires instead of proactively building for the future.

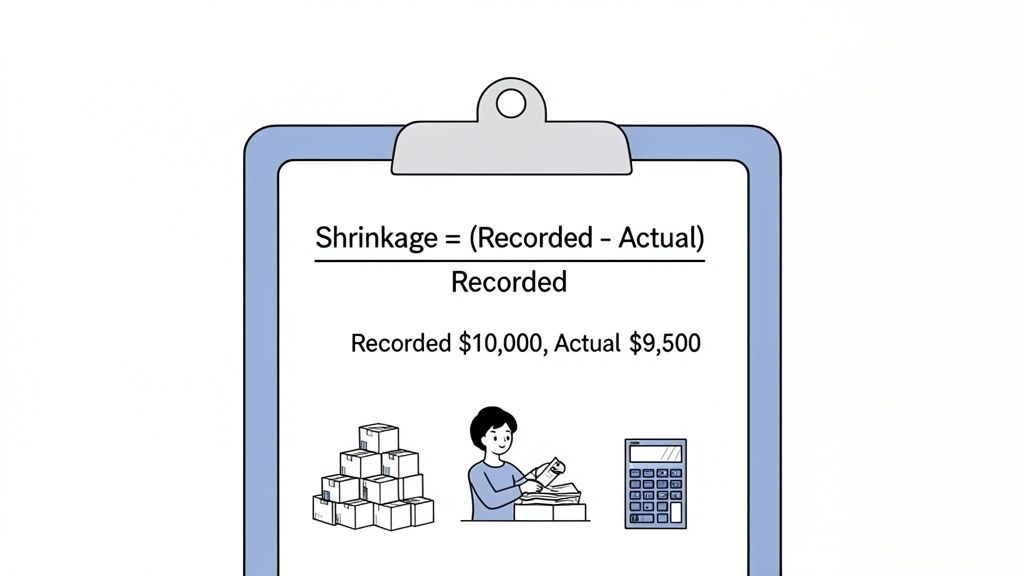

You can’t fix what you don’t measure. To get a real handle on inventory shrinkage, you first need to put a number on it. Calculating your shrinkage rate is the first step, turning a vague operational headache into a concrete figure you can actually work to improve.

The process is more straightforward than you might think. It all boils down to a simple formula that compares what your books say you have versus what’s physically sitting in your warehouse.

At its core, calculating your shrinkage rate is a three-step dance. The result is a simple percentage that tells you exactly how much of your inventory value has vanished over a certain period.

Here’s the formula:

Shrinkage Rate % = (Recorded Inventory Value – Actual Inventory Value) / Recorded Inventory Value x 100

Let’s quickly break down what each piece of that equation means for your D2C store.

Let's put this into action. Imagine you run a Shopify store called "Urban Bloom" that sells home goods. At the beginning of the quarter, you check your inventory report, and it shows you have $120,000 worth of products on hand. That’s your recorded inventory value.

Time for a physical count. Your team goes through the warehouse, clipboard in hand (or scanner, more likely), and carefully counts every single item. When all is said and done, you find the actual value of your on-hand stock is $117,000.

Now, let's plug those numbers into the formula:

To get the shrinkage rate as a percentage, you just do one more quick calculation:

($3,000 / $120,000) x 100 = 2.5%

Just like that, Urban Bloom’s shrinkage rate for the quarter is 2.5%. This single number is incredibly powerful. It gives you a clear benchmark to track over time, helping you see if your loss prevention efforts are actually making a difference.

While the shrinkage rate is the main event, tracking a few related Key Performance Indicators (KPIs) gives you a much fuller picture of your inventory health.

A big one is your Inventory Accuracy Percentage. This metric is basically the flip side of your shrinkage rate. It tells you how much of your inventory is correctly accounted for.

The formula is just as simple:

Inventory Accuracy % = (Actual Inventory Value / Recorded Inventory Value) x 100

Using our Urban Bloom example, their inventory accuracy would be:

($117,000 / $120,000) x 100 = 97.5%

Most D2C brands should be aiming for an inventory accuracy rate of 98% or higher. Regularly calculating and tracking these numbers is what moves you from just reacting to problems to proactively managing your inventory and protecting your bottom line.

Alright, knowing your shrinkage rate is the first step. But the real win comes from actively pushing that number down. It's time to move from diagnosis to action.

For any e-commerce owner, figuring out how to reduce shrinkage boils down to a smart mix of tighter processes, team training, and the right tech. This isn’t just about protecting your products; it's about protecting your bottom line.

Let's dive into three core areas where you can take concrete steps—right now—to secure your inventory and plug those profit leaks for good.

Your warehouse is the heart of your operation, and honestly, it's where most preventable losses happen. Getting your physical processes buttoned up is the bedrock of any loss prevention plan. And it all starts the moment a new shipment arrives.

Your employees are your first line of defense against shrinkage, but they can't be effective without the right training and structure. When your team understands how much shrinkage actually costs the business, they're far more likely to be vigilant and follow procedures to the letter. This is about building a culture of ownership, not suspicion.

A huge piece of this is setting up clear access controls. Not every employee needs to be in all areas of the warehouse or have access to every function in your inventory software. By limiting access based on job roles, you shrink the opportunity for both intentional theft and accidental mistakes.

Training isn't a one-and-done onboarding task. Think of it as an ongoing conversation. Regular refreshers on things like proper inventory handling, spotting return fraud, and the importance of accurate data entry will keep best practices top of mind and your team sharp.

Also, make sure your return process is airtight. Your staff needs to be trained to inspect returned items thoroughly. Are they the correct product? Are they actually in sellable condition? Do they match the original order? This helps shut down fraudulent returns, which are a growing headache for online retailers.

Finally, the right technology can be a massive force multiplier for all your other efforts. Let's face it, manual processes are magnets for human error, and that's a major driver of administrative shrinkage.

Here are a few key pieces of tech to get in place:

Most traditional methods for dealing with inventory shrinkage are, unfortunately, reactive. You do a big physical count, find a major discrepancy, and then start the detective work to figure out what went wrong. The problem is, the profit has already walked out the door. It’s like getting a security alert that your warehouse was broken into yesterday—the damage is already done.

This is where modern AI and analytics completely flip the script. They move you from a reactive, backward-looking position to a proactive one. Instead of just tallying up historical losses, these tools act like an early warning system, spotting the subtle signs of shrinkage before they turn into huge financial hits.

Picture an intelligent system that's constantly watching your operational data—your sales velocity, inventory levels, return rates, and receiving logs. That's exactly what AI-powered analytics platforms do. They take the time to learn the normal rhythm of your business, and once they have that baseline, they flag anything that seems out of place.

This kind of oversight can uncover issues that you’d almost certainly miss with manual checks alone.

For instance, an AI might detect that a specific product's stock is going down 20% faster than its actual sales velocity can explain. An anomaly like that is a massive red flag. It points you directly toward potential problems like internal theft, recurring fulfillment errors, or even unrecorded damages that are quietly eating into your margins.

By bringing these discrepancies to your attention in near real-time, you can investigate right away, not months from now during your next big audit. This is the heart of an effective inventory monitoring system—turning raw data into actionable alerts that prevent losses.

Beyond just flagging weird activity, analytics also shield your business from the downstream effects of bad data. When shrinkage gets mistaken for legitimate sales, it creates "ghost demand," which can absolutely wreck your forecasting and reordering strategy.

An AI-driven, adaptive forecasting engine can tell the difference between real sales trends and inventory drops caused by shrinkage. This stops you from over-ordering a product that isn’t truly selling, protecting your cash flow and preventing costly overstocks.

Let's look at a real-world example. A D2C wellness brand sells a popular, high-value collagen powder. An AI platform analyzes their receiving data and flags a recurring pattern: shipments from one particular vendor are consistently 3-5% short of the invoiced amount.

The system alerts the operations manager, who immediately puts a stricter receiving process in place for that vendor. That single insight not only saves the brand thousands on that one SKU but also prevents future stockouts that would have been caused by having inaccurate on-hand counts.

This proactive approach gives you the power to find and fix the root causes of inventory shrinkage. It transforms your data from a simple record of the past into a strategic tool for protecting your future profits.

Let's be real—a great strategy is useless if it doesn't become a habit. The key to actually minimizing shrinkage is turning these big ideas into simple, repeatable actions for your team.

Think of this as your go-to checklist for building a solid loss prevention routine. It breaks everything down into manageable daily, weekly, and quarterly tasks.

Of course. Here is the rewritten section, crafted to sound like an experienced human expert, following all the provided guidelines and matching the example blog post style.

As you start digging into inventory shrinkage, a few questions always pop up. Let's tackle the most common ones we hear from Shopify merchants so you can get a clearer picture of how to protect your own bottom line.

You'll often hear the retail average is around 1.6% of sales, but honestly, that number can be misleading. "Acceptable" is highly specific to your niche. If you're selling high-end electronics, for example, your risk is naturally higher than a store selling low-cost apparel.

My advice? Stop chasing industry averages. The real goal is continuous improvement. First, figure out what your current shrinkage rate is—that's your baseline. From that moment on, your only job is to push that number down, month after month. Aiming to get it under 1% is a fantastic and totally achievable starting point.

That big, wall-to-wall physical count? It’s a massive headache, and most businesses only do it once a year for the accountants. But waiting 12 months to find out you have a problem is a recipe for disaster. You can’t fix what you don’t know is broken.

This is why we're huge advocates for cycle counting. Instead of a once-a-year ordeal, you count small, designated sections of your warehouse every day or week. It’s far less disruptive and helps you catch discrepancies almost as they happen. You'll find and fix those small leaks long before they turn into a flood discovered during your annual audit.

In a word, no. Think of your inventory management system like the dashboard in your car—it’s brilliant at telling you there’s a problem, like a check engine light. It can show you that your inventory numbers are off, but it can’t actually get under the hood and fix the leak.

To truly stop shrinkage, you have to pair that software with solid operational processes. This means well-trained staff who know what to look for, secure warehouse procedures, and using smart analytics to figure out the why behind the numbers your system is flagging. The software points you in the right direction; your team and your strategy do the rest.

Ready to move from reactive counts to proactive prevention? Tociny.ai uses AI-powered analytics to flag anomalies and predict demand, helping you stop shrinkage before it hurts your bottom line. Get early access and protect your profits today.

Tociny is in private beta — we’re onboarding a few select stores right now.

Book a short call to get early access and exclusive insights.